Hydraulic Cylinders

HIGH QUALITY HIGH PRECISE MANUFACTURER & SUPPLIER

What Is A Hydraulic Cylinders?

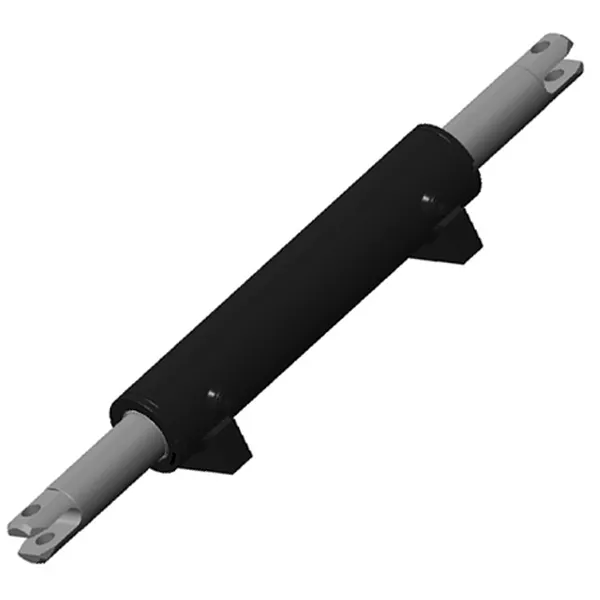

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear force and motion. It is an essential component of hydraulic systems and is widely used in various applications across industries such as construction, manufacturing, agriculture, and transportation.

The hydraulic cylinder consists of a cylindrical barrel, a piston, a piston rod, and various seals. The barrel is typically made of steel and houses the piston, which divides the cylinder into two chambers: the rod side and the cap side. The piston rod extends from the piston and protrudes through a sealed opening in one end of the cylinder.

Hydraulic fluid, usually oil, is pressurized into one chamber of the cylinder, causing the piston to move. As the fluid pressure increases, it pushes against the piston, which, in turn, pushes the piston rod and generates linear force. The movement of the piston rod can be either extending or retracting, depending on the direction of fluid flow and the configuration of the hydraulic system.

Hydraulic Cylinders For Sale

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roller Press Cylinder

-

Cement Equipment Vertical Mill Cylinder

-

Crane Counterweight Hydraulic Cylinder

-

Crane Luffing Hydraulic Cylinder

How To Maintain Hydraulic Cylinders?

Here are some key maintenance practices for hydraulic cylinders:

Periodic Inspections: Perform a visual inspection of the hydraulic cylinder for signs of leakage, damage, or wear.

Keep it Clean: Keep the hydraulic cylinder and the area around it clean to prevent the build-up of dirt, debris, or contaminants that can cause damage or affect performance

Lubrication: Follow manufacturer's lubrication recommendations.

Seal Inspection and Replacement: Check seals regularly for signs of wear, cracks, or leaks.

Fluid Maintenance: Monitor hydraulic fluid regularly and maintain proper fluid levels.

Pressure and Performance Testing: Regularly test the pressure and performance of hydraulic cylinders to ensure they are operating within specified parameters.

How To Measure Hydraulic Cylinder?

Bore Diameter:

Use a caliper or micrometer to measure the internal diameter of the cylinder bore. Ensure the measurement is taken at a few different points along the length to account for any potential variations.

Record the largest diameter measurement obtained.

Rod Diameter:

Measure the diameter of the rod using a caliper or micrometer. Take measurements at multiple points along the length to account for any tapering.

Record the smallest diameter measurement obtained.

Stroke Length:

Extend the cylinder to its maximum length and measure the distance from one end of the rod to the other. This measurement represents the stroke length.

Overall Length:

Measure from the base or mounting surface to the opposite end of the cylinder, accounting for any protruding components or fittings.

Application of Hydraulic Cylinders

Construction Equipment

Hydraulic cylinders are extensively used in construction machinery such as excavators, bulldozers, loaders, cranes, and backhoes.

Industrial Machinery

Hydraulic cylinders are employed in a wide range of industrial machinery, including hydraulic presses, stamping machines, injection molding machines, and metal forming equipment.

Automotive Applications

Hydraulic cylinders are utilized in various automotive applications, such as hydraulic suspension systems, convertible top mechanisms, hydraulic brakes, and hydraulic power steering systems.

Material Handling

Hydraulic cylinders play a crucial role in material handling equipment like forklifts, pallet jacks, and scissor lifts.

Agriculture Equipment

Hydraulic cylinders are found in agricultural machinery such as tractors, harvesters, sprayers, and loaders.

Aerospace and Defense

Hydraulic cylinders are employed in aircraft landing gear systems, flight control surfaces, cargo loading systems, and various defense applications.

Hydraulic Cylinders Advantage

High Force Output

Hydraulic cylinders can generate high levels of force, allowing them to handle heavy loads and perform tasks that require substantial power

Precise Control

Hydraulic systems provide precise and accurate control over the movement of hydraulic cylinders. By regulating the flow of hydraulic fluid, the speed and position of the cylinder can be precisely controlled, allowing for smooth and controlled motion

Compact Design

Hydraulic cylinders are known for their compact design relative to the amount of force they can generate. They can deliver substantial force output in a relatively small package, making them suitable for applications where space is limited or weight needs to be minimized.

Unlock Efficiency and Precision with the Hydraulic Cylinder

The Hydraulic Cylinder is meticulously engineered to provide precise control over movement and force. With its advanced design and high-quality construction, it ensures accurate and repeatable performance, allowing you to achieve the desired results with exceptional precision.

Latest Articles

China Hot selling High Quality Hydraulic Cylinder Oil Cylinder Rod Type Hydraulic Cylinder vacuum pump

China Hot selling Long Stroke 100 50 Ton Press Ryco CZPT Type Mini Small Lift Double Single Acting Piston Telescopic Hydraulic Cylinder for Sale with Manufacturers Price vacuum pump oil

China Hot selling Spanish Cicrosa Cylinder Hydraulic Cylinder Vehicle Self-Locking Cylinder vacuum pump connector

WHY CHOOSE US?

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!