Factory OEM Hydraulic Cylinders Forklift Single Acting Hydraulic Cylinder Lift Industrial Vehicle Hydraulic Cylinders

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

A single acting forklift hydraulic cylinder is a type of hydraulic cylinder that only moves in one direction. It is used to lift the load on a forklift. The cylinder has a piston that moves inside a cylinder barrel. When hydraulic fluid is pumped into the cylinder, it pushes the piston and the load up. When the fluid is released, the spring inside the cylinder returns the piston and the load to the down position.

Single acting forklift hydraulic cylinders are typically made of steel and have a chrome-plated piston. They are available in a variety of sizes and strokes to accommodate different forklift models and loads.

The main advantage of a single acting forklift hydraulic cylinder is that it is simpler and less expensive than a double acting cylinder. However, it also has some disadvantages. For example, it can only lift the load, not lower it. This means that the forklift operator must manually lower the load by using the brakes or the tilt mechanism.

Single acting forklift hydraulic cylinders are a common and effective way to lift loads on forklifts. They are simple, reliable, and relatively inexpensive.

Here are some of the key features of a single acting forklift hydraulic cylinder:

- Only moves in one direction (pushes)

- Powered by hydraulic fluid

- Has a piston and cylinder barrel

- Contains a spring to return the piston to the down position

- Made of steel and has a chrome-plated piston

- Available in a variety of sizes and strokes

Single Acting Forklift Hydraulic Cylinder Part Structure:

|

1

|

Cylinder Housing assy

|

|

2

|

U-Ring

|

|

3

|

Back-Ring

|

|

4

|

Dust Wiper

|

|

5

|

Piston Rod

|

|

6

|

Steel Ball

|

|

7

|

Du Bush

|

|

8

|

O-Ring

|

Single Acting Forklift Hydraulic Cylinder Key Attributes:

| Condition: | New | Product name: | Single Acting Forklift Hydraulic Cylinder |

| Warranty: | 1 Year | Application: | Industrial vehicle/forklift lift |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Farms | Color: | Customer Requirement |

| Weight (KG): | 6 | Material: | 20#/45# Steel |

| Video outgoing inspection: | Provided | Acting type: | Single Acting |

| Machinery Test Report: | Provided | Seals: | Hallite,parker, NOK,Shamban |

| Marketing Type: | Ordinary Product | Certificate: | ISO9001:2015 |

| Warranty of core components: | 1 Year | Keyword: | Steering lift tilt extension |

| Core Components: | Piston rod, Piston | MOQ: | 1pcs |

| Standard or Nonstandard: | Nonstandard | Brand: | EPT |

| Structure: | Piston Cylinder | Packaging Details: | Crate, pallet, or based on customer's requirement |

| Power: | Hydraulic | Supply Ability | 100,000 Piece/Pieces per Month |

| Body Material: | Steel | Port: | Shanghai/Ningbo |

Single Acting Forklift Hydraulic Cylinder Parameters:

| Item | Description |

| Product Name | Custom-made hydraulic Cylinder for industrial vehicle/forklift lift |

| Certificate: | ISO9001, ISO4001, ISO 45003 |

| Production Capacity: | 1200,000 pcs per year |

| Sample Time | Based actual type |

| Brand | EPT or customer's logo |

| Service | OEM & ODM |

| Seal brand | Parker,NOK, BUSAK SHAMBAN |

| Delivery Time | Based on order quantity. |

| Business Type | Manufacturer & Exporter |

Single Acting Forklift Hydraulic Cylinder Vs Double Acting Forklift Hydraulic Cylinder:

Single-acting and double-acting forklift hydraulic cylinders are two variations commonly used in hydraulic systems of forklifts. While they serve the same purpose of lifting and lowering loads, there are significant differences in their operation and functionality. Here's a comparison between the two:

Single-Acting Forklift Hydraulic Cylinder:

- Operation: Single-acting hydraulic cylinders operate in one direction only, usually providing force during the extension stroke. The retraction of the piston rod is typically accomplished by using a separate mechanism, such as the weight of the load or a spring.

- Hydraulic Fluid: Single-acting cylinders require hydraulic fluid to be supplied to only one side of the piston head. The fluid applies pressure to extend the piston rod and lift the load. During retraction, the hydraulic fluid is released, and the weight of the load or spring returns the piston rod.

- Design: Single-acting cylinders are simpler in design compared to double-acting cylinders. They have fewer components and require less maintenance.

- Cost: Single-acting cylinders are generally more affordable than double-acting cylinders due to their simpler construction and operation.

- Applications: Single-acting cylinders are suitable for applications where the load can be lowered by gravity or assisted by other means. They are commonly used in forklifts with a counterweight system that aids in the lowering process.

Double-Acting Forklift Hydraulic Cylinder:

- Operation: Double-acting hydraulic cylinders can generate force in both the extension and retraction strokes. They consist of two chambers on either side of the piston head, allowing hydraulic fluid to be applied alternately to extend and retract the piston rod.

- Hydraulic Fluid: Double-acting cylinders require hydraulic fluid to be supplied to both sides of the piston head. Pressurized fluid extends the piston rod in one direction, and fluid is then applied to the opposite side to retract it.

- Design: Double-acting cylinders have a more complex design compared to single-acting cylinders. They require additional seals and components to facilitate fluid flow in both directions.

- Control: Double-acting cylinders provide greater control over load movements as operators can apply force in both the lifting and lowering actions.

- Applications: Double-acting cylinders are suitable for applications where precise control over load movement is required. They are commonly used in forklifts that need precise positioning and control during lifting and lowering operations.

In summary, the choice between single-acting and double-acting forklift hydraulic cylinders depends on the specific requirements of the forklift application. Single-acting cylinders are simpler and more cost-effective, suitable for applications where gravity or external mechanisms assist in load lowering. Double-acting cylinders provide more control and are ideal for precise load positioning and control.

Single Acting Forklift Hydraulic Cylinder Features:

Single acting forklift hydraulic cylinders for all industries. We can build, supply new, and repair cylinders for forklift, earth moving, marine, press, crane, telescopic, shear, excavator, and chip dump applications. We also have the capabilities, experience, and technical knowledge to manufacture new cylinders and custom-build cylinders. We can handle any hydraulic cylinder needs, from smaller application hydraulic steering cylinders to very large cylinders (for example, cylinders on large mining equipment). Contact us for pricing and availability or if you need a custom single acting forklift hydraulic cylinder.

● 3000PSI Rated pressure, 6000PSI testing pressure.

● Imported world-famous brands and Chinese top brands sealing systems.

● High quality Cold Drawn steel tube, with good rigidity.

● CNC Rolled tube inner surface, with roughness of 0.2~0.4um.

● Superior strength chrome-plated rod, anticorrosion for a long life.

● High-grade Ductile Iron bar directly machined Gland and Piston, with high strength.

● Heavy-duty welded construction, automatic welding for good quality.

● 100% factory tested under at least 1.5 times the rated pressure.

We Also Can Customized Hydraulic Cylinders:

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce Industrial vehicle hydraulic cylinders, Aerial work vehicle hydraulic cylinders, Agricultural Machinery hydraulic cylinders, Construction machinery hydraulic cylinders, Forklift hydraulic cylinders, Crane hydraulic cylinders, and Sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

China Forklift Hydraulic Cylinder Manufacturers

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

The machining shop is equipped with custom-made tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other relevant equipment, which can handle the machining work of cylinder tubes with 400mm Max ID and with 6 meters of Max length.

We have a fully automatic water-based paint coating line for small and medium cylinders, which realizes automatic loading and unloading and automatic spraying by robots, with a designed production capacity of 4,000 pieces per shift. We have another semi-automatic painting line for large-scale cylinders, which is driven by a power chain, and the design capacity is 60 crates per shift.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

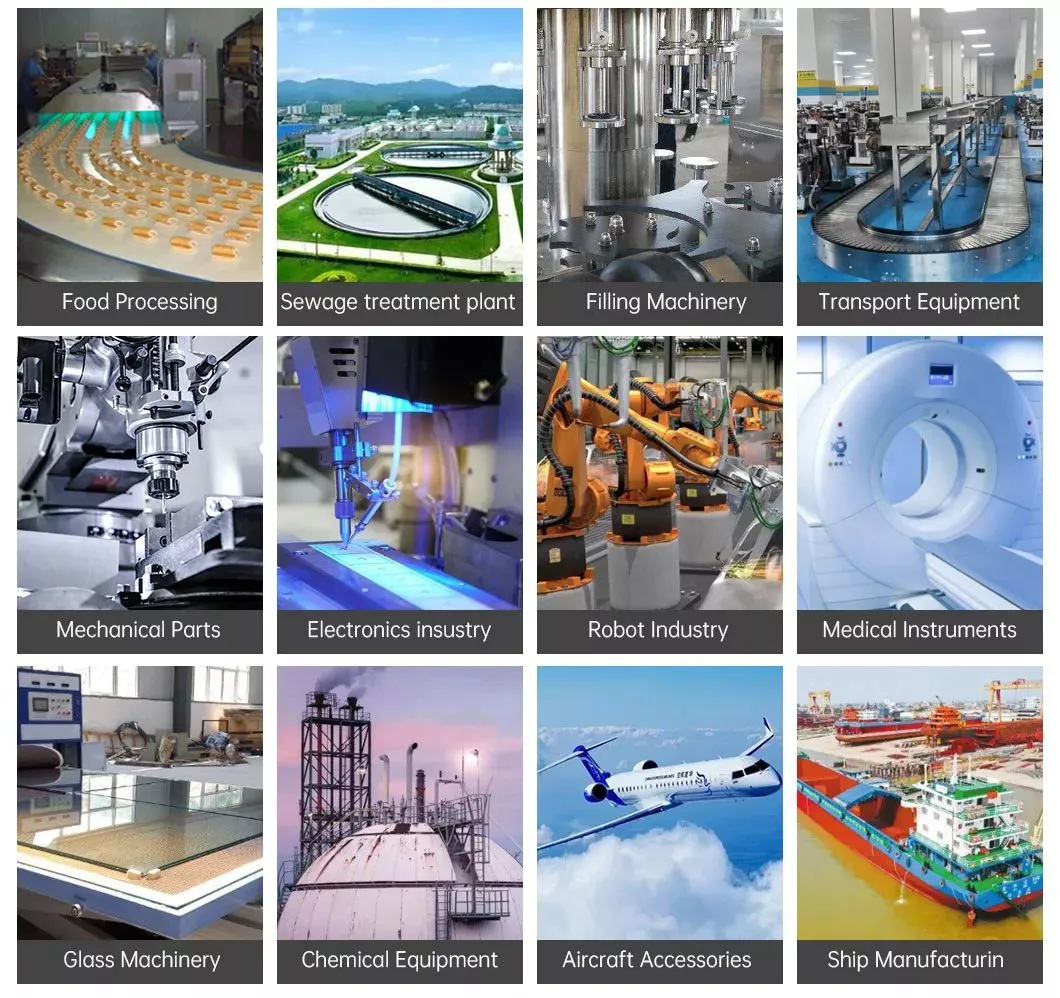

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder