Offshore Crane A Type Mast Crane Luffing Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

An offshore crane A type mast crane luffing cylinder is a hydraulic cylinder that is used to control the horizontal angle of the mast of an A-frame offshore crane. It is a critical component of the crane, as it allows the operator to adjust the mast angle to ensure that the load is safely lifted and positioned.

Offshore crane A type mast crane luffing cylinders are typically large and heavy due to the need to provide sufficient thrust force to overcome the weight of the crane and the load. They are also designed to withstand the harsh environmental conditions that offshore cranes often operate in, such as salt spray, high winds, and extreme temperatures.

Offshore crane A type mast crane luffing cylinders are typically made of high-strength steel and are coated with a corrosion-resistant material. They are also equipped with a number of features to ensure reliability and safety, such as:

- A double-acting piston design to provide both pushing and pulling force

- A counterbalance valve to prevent over-extending the cylinder

- A pressure relief valve to prevent the cylinder from exceeding its safe working pressure

- A temperature sensor to monitor the cylinder's operating temperature and prevent overheating

Offshore crane A type mast crane luffing cylinders are an essential component of offshore cranes and play a vital role in ensuring the safe and efficient operation of these cranes.

Offshore Crane A Type Mast Crane Luffing Cylinder Specifications:

| Product Name | Offshore Crane A Type Mast Crane Luffing Cylinder |

| Features: | Provide thrust force and pulling force used to adjust the horizontal angle of the crane's forearm |

| Bore diameter: | Up to 580mm |

| Rod diameter: | Up to 400mm Stroke up to 5170mm |

| Thrust force /Pulling force: | Maximum 8454KN/3589KN (Cylinders diameter 580mm/pressure 32MPa) |

| Applications: | Offshore Crane |

Benefits of Offshore Crane A Type Mast Crane Luffing Cylinder:

Here are some of the key advantages of offshore crane A type mast crane luffing cylinders:

1. High thrust force: Offshore crane A type mast crane luffing cylinders are designed to provide a high thrust force to overcome the weight of the crane and the load. This allows the operator to safely lift and position heavy loads.

2. Reliability: Offshore crane A type mast crane luffing cylinders are designed to be reliable and withstand the harsh environmental conditions that offshore cranes often operate in.

3. Safety features: Offshore crane A type mast crane luffing cylinders are equipped with a number of safety features to prevent over-extending the cylinder, exceeding the safe working pressure, and overheating.

Offshore crane A type mast crane luffing cylinders are used in a variety of offshore applications, including:

- Oil and gas exploration and production

- Wind farm construction and maintenance

- Subsea construction and maintenance

- Heavy lift operations

Offshore crane A type mast crane luffing cylinders are a critical component of offshore operations and play a vital role in ensuring the safe and efficient operation of offshore cranes.

Choose the Right A Type Mast Crane Luffing Cylinder for Offshore Crane:

When choosing the right A-type mast crane luffing cylinder for an offshore crane, several factors need to be considered. Here are some key considerations:

Load Capacity: Determine the maximum load capacity required for your offshore crane. This will help you select a luffing cylinder capable of handling the specified load.

Stroke Length: Consider the required stroke length, which is the distance the luffing cylinder extends and retracts. The stroke length should be sufficient to cover the required range of motion for your offshore crane.

Operating Environment: Offshore cranes operate in harsh environments, including saltwater exposure, high winds, and potentially corrosive atmospheres. Choose a luffing cylinder that is specifically designed for offshore applications and offers corrosion resistance and durability.

Safety and Reliability: Offshore operations demand high levels of safety and reliability. Ensure that the luffing cylinder meets industry safety standards and has a proven track record of reliable performance in offshore conditions.

Maintenance and Service: Consider the ease of maintenance and availability of service for the luffing cylinder. Offshore cranes may require periodic inspections and maintenance, so it's important to choose a cylinder that is easily accessible for servicing and has readily available spare parts.

Integration Compatible: The luffing cylinder should be compatible with your offshore crane's overall design and integration requirements. Consider factors such as mounting options, connection interfaces, and hydraulic system compatibility.

China Offshore Crane Cylinder Manufacturers

The special application environment at sea brings great challenges to offshore cranes. On the one hand, it needs to have higher reliability and smooth operation to ensure positioning accuracy and transportation efficiency. On the other hand, there are high requirements for its corrosion resistance and low-temperature resistance. HZPT can provide standard nickel-chromium coatings, plasma spray coatings, supersonic flame spray coatings, other corrosion-resistant technologies, and integral stainless steel piston rods according to customer needs and the actual use environment of offshore cranes.

For equipment with low-temperature resistance requirements, materials with excellent low-temperature impact properties will also be used to ensure that the crane is sufficient to withstand harsh environments. In addition, HZPT provides luffing cylinders for cranes that provide thrust force and pulling force. Its innovative structural design makes the weight lighter and improves the efficiency of the entire hydraulic system. HZPT can provide a complete set of hydraulic cylinders according to the needs of offshore cranes, such as main boom luffing cylinders, folding arm tilt cylinders, mast crane luffing cylinders, etc. It can be customized according to customer requirements.

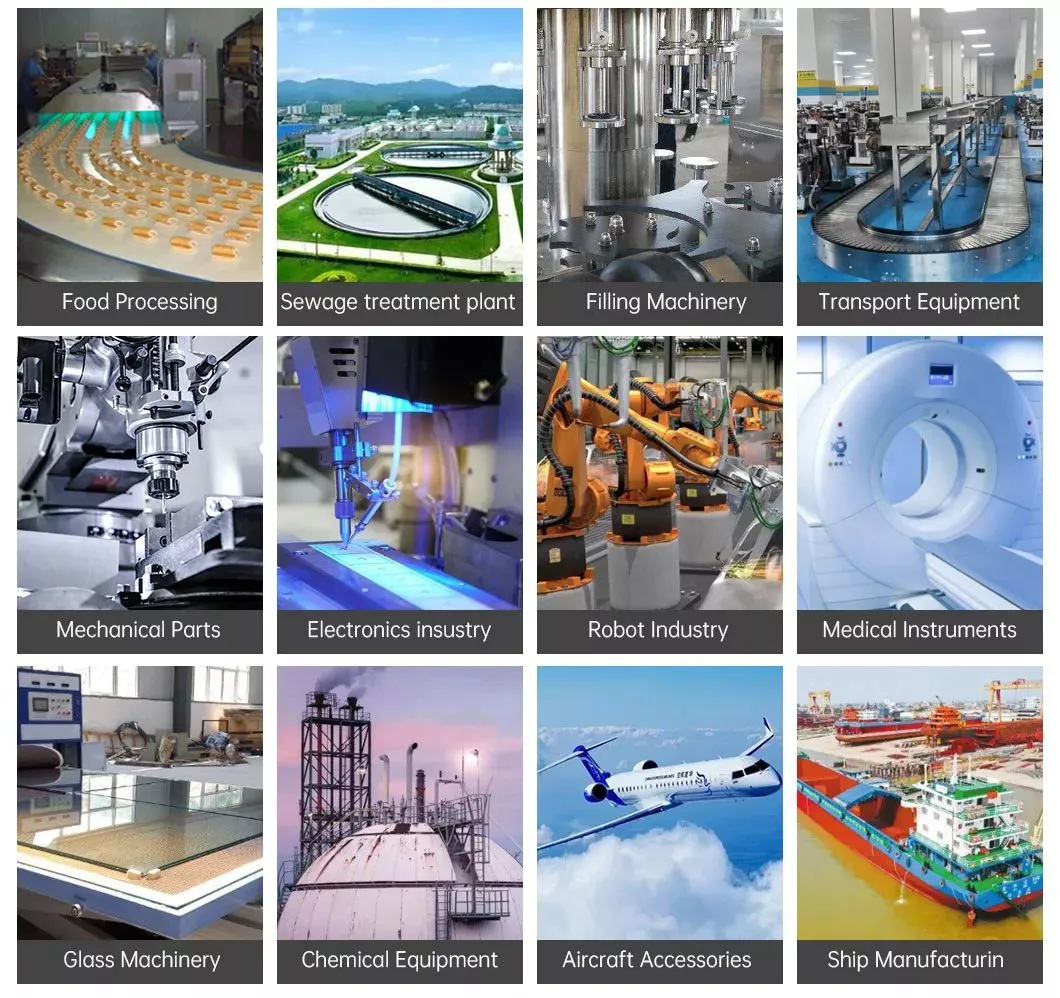

Moreover, we go beyond offshore crane cylinders. We also supply a diverse range of hydraulic cylinders, including industrial vehicle hydraulic cylinders, aerial work vehicle cylinders, mobile machinery cylinders, industrial engineering cylinders, construction machinery cylinders, forklift hydraulic cylinders, agricultural machinery cylinders, crane hydraulic cylinders, sanitation machinery cylinders, excavator hydraulic cylinders, offshore hydraulic cylinders, energy technology cylinders, tunnel boring machine cylinders, and more. Our extensive product lineup caters to various industries and applications, providing solutions for your hydraulic needs.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder