Injection Molding Machine Mold Opening and Closing Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

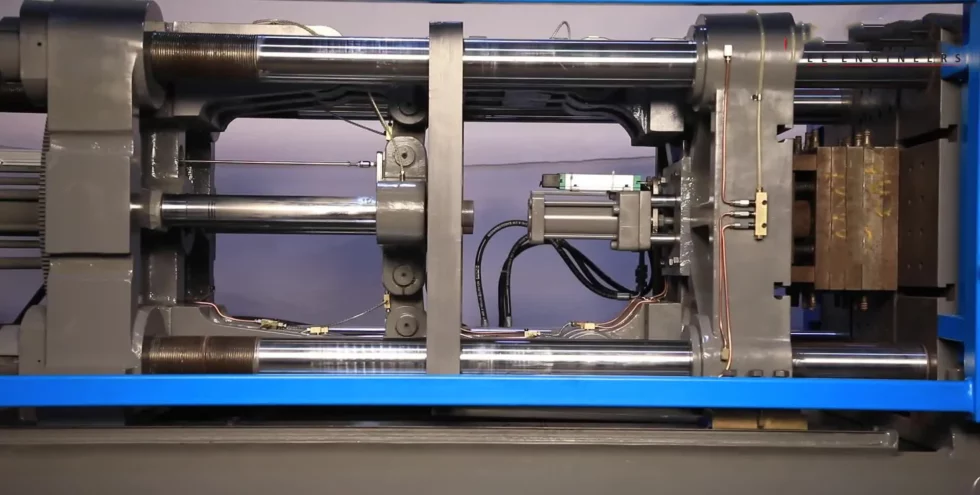

The mold opening and closing cylinder is a hydraulic cylinder that is used to open and close the mold in an injection molding machine. It is typically a double-acting cylinder, which means that it can move in both directions. The piston rod of the cylinder is connected to the movable platen of the mold, and the force of the hydraulic fluid is used to move the platen open or closed.

The mold opening and closing cylinder is a critical component of the injection molding machine, as it ensures that the mold is properly opened and closed during each cycle. The speed and force of the cylinder can be adjusted to accommodate different mold sizes and applications.

The typical open and close time for the mold opening and closing cylinder is 2 to 5 seconds. This time can vary depending on the size and weight of the mold, as well as the force required to open and close it. The mold opening and closing cylinder is a critical component of the injection molding machine, and it must be properly maintained to ensure its long-term operation. Regular inspection and lubrication are essential to prevent leaks and damage to the cylinder.

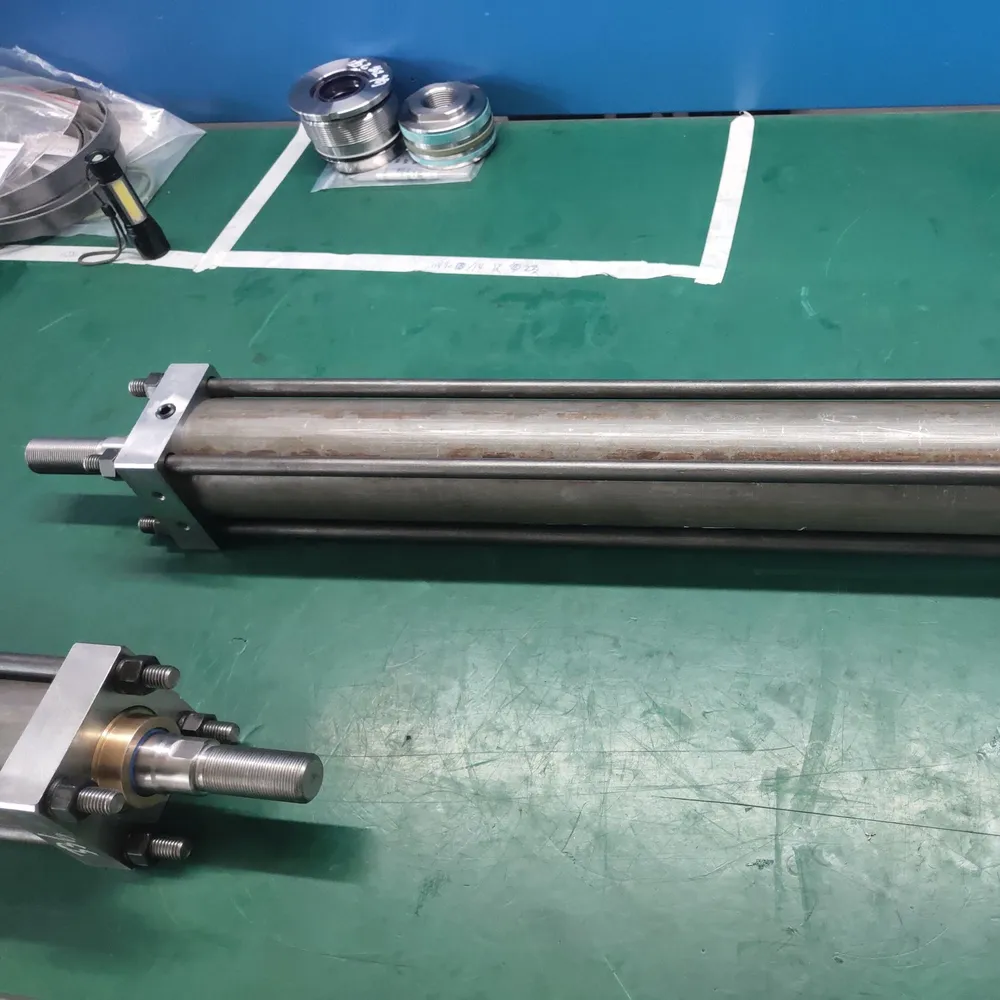

Injection Molding Machine Mold Opening and Closing Cylinder Specifications:

| Product Name | Injection Molding Machine Mold Opening and Closing Cylinder |

| Features: | Control the opening and closing of the mold |

| Bore diameter: | 50mm~140mm |

| Rod diameter: | 28mm~100mm Stroke≤700mm |

| Thrust force: | Maximum 384KN (Bore diameter: 140mm/pressure25MPa) |

| Applications: | Injection Molding Machine |

Features of Mold Opening and Closing Cylinder for Injection Molding Machine

The injection molding machine mold opening and closing cylinder offers several advantages in the injection molding process. Here are some key benefits:

1. Precise and Controlled Movement: The mold opening and closing cylinder allows for precise and controlled movement of the mold halves. This ensures accurate alignment and positioning of the mold, resulting in high-quality molded parts with consistent dimensions.

2. High Clamping Force: The hydraulic cylinder used in the mold opening and closing system can generate significant clamping force. This force is essential for securely holding the mold halves together during the injection process, preventing any leakage or flash formation.

3. Fast Cycle Times: The mold opening and closing cylinder enables quick mold movements, resulting in shorter cycle times. This is crucial for achieving high production efficiency and increasing the output of the injection molding machine.

4. Versatility: The mold opening and closing cylinder can accommodate a wide range of mold sizes and configurations. It can be adjusted to handle different mold types, allowing for flexibility in production and the ability to mold various part designs.

5. Reliability and Durability: The mold opening and closing cylinder is designed to withstand the high pressures and repetitive movements involved in the injection molding process. It is built with robust materials and precise engineering, ensuring long-term reliability and durability.

6. Safety Features: Many mold opening and closing cylinders are equipped with safety features to protect operators and prevent accidents. These features may include sensors, monitors, and emergency stop mechanisms, ensuring a safe working environment.

Maintenance of Injection Molding Machine Mold Opening and Closing Cylinder

Proper maintenance of the injection molding machine mold opening and closing cylinder is crucial to ensure its optimal performance and longevity. Here are some maintenance practices to consider:

(1) Regular Inspection: Perform routine visual inspections of the mold opening and closing cylinder to check for any signs of wear, leaks, or damage. Inspect the hydraulic lines, seals, and connections for any abnormalities. If any issues are detected, address them promptly to avoid further damage.

(2) Lubrication: Follow the manufacturer's guidelines for lubricating the mold opening and closing cylinder. Proper lubrication helps reduce friction and wear, ensuring smooth operation. Use the recommended lubricants and apply them according to the specified intervals.

(3) Hydraulic Fluid Maintenance: Maintain the hydraulic fluid at the appropriate level and monitor its condition. Regularly check the fluid for contamination, such as dirt or moisture, and replace it if necessary. Follow the manufacturer's recommendations for fluid type and change intervals.

(4) Seal Replacement: The seals in the mold opening and closing cylinder are critical for preventing hydraulic fluid leaks. Inspect the seals regularly and replace them if they show signs of wear, damage, or leakage. Proper sealing is essential for maintaining the hydraulic cylinder's performance and preventing downtime.

(5) Pressure and Speed Calibration: Periodically check and calibrate the pressure and speed settings of the mold opening and closing cylinder. Ensure that they are within the recommended ranges and are properly adjusted for the specific molding requirements. This helps maintain precise control and prevent excessive stress on the cylinder components.

(6) Cleaning: Keep the mold opening and closing cylinder clean from dirt, debris, and any other contaminants. Regularly remove any accumulated residue or foreign particles that may affect its operation. Use appropriate cleaning methods and avoid using abrasive materials that could damage the cylinder's surface.

(7) Professional Maintenance: Engage qualified technicians or maintenance personnel to perform regular maintenance and inspections of the injection molding machine, including the mold opening and closing cylinder. They have the expertise to identify and address any potential issues, ensuring the cylinder's optimal performance.

China Injection Molding Machine Cylinder Manufacturers

In 30 years of focusing on innovation, HZPT has reached the forefront of the world’s hydraulic industry in terms of both production scale and technical level. Meanwhile, HZPT is now a widely recognized benchmarking enterprise in the domestic hydraulic industry. Headquartered in Hangzhou, HZPT has founded five hydraulic R&D centers in China, Germany, the United States, Japan, and Mexico, and ten manufacturing bases worldwide. HZPT the establishment of a high-precision foundry and a pump & valve factory, HZPT has mastered the key to developing and manufacturing more advanced hydraulic transmission and control components to supply high-pressure cylinders, hydraulic pump valves, motors, precision castings, and the complete hydraulic system. Well sold in over 20 countries and regions, the products are widely applied in various fields such as mobile machinery, agricultural machinery, industrial engineering, offshore, energy technology, and tunnel boring machines.

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders in China. In 2020, the domestic market share was around 29%. We produce industrial vehicle hydraulic cylinders, aerial work vehicle hydraulic cylinders, mobile machinery cylinders, industrial engineering hydraulic cylinders, construction machinery hydraulic cylinders, forklift hydraulic cylinders, crane luffing hydraulic cylinders, and sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder