Injection Molding Machine Reciprocating Cylinder (Mold Shifting Cylinder)

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

An injection molding machine reciprocating cylinder is a piston-and-cylinder assembly that is used to inject molten plastic into a mold. The cylinder is typically made of steel or aluminum and is fitted with a piston that is driven by a hydraulic or pneumatic actuator. The cylinder is connected to the mold through a nozzle, which allows the molten plastic to flow into the mold cavity.

The reciprocating cylinder is a critical component of the injection molding machine and is responsible for delivering the molten plastic to the mold at precise pressure and speed. The cylinder must be able to withstand the high pressures and temperatures generated during the injection molding process, and it must also be able to provide a smooth and consistent motion of the piston.

There are two main types of reciprocating cylinders used in injection molding machines: direct-acting cylinders and indirect-acting cylinders. Direct-acting cylinders are driven directly by the hydraulic or pneumatic actuator, while indirect-acting cylinders are driven by a linkage system. Indirect-acting cylinders are typically used in larger injection molding machines, as they can provide more force and a smoother motion.

The injection molding machine reciprocating cylinder is a complex component, but it is essential for the proper operation of the injection molding machine. By understanding the basics of the reciprocating cylinder, you can better understand how injection molding machines work.

Injection Molding Machine Reciprocating Cylinder Specifications:

| Product Name | Injection Molding Machine Reciprocating Cylinder |

| Features: | Quick mold shifting, also called mold shifting cylinder |

| Bore diameter: | 63mm~180mm |

| Rod diameter: | 45mm~125mm Stroke≤4000mm |

| Thrust force: | Maximum 407KN (Bore diameter: 180mm/pressure16MPa) |

| Applications: | Injection Molding Machine |

Injection Molding Machine Reciprocating Cylinder Benefits:

Reciprocating cylinders are commonly used in injection molding machines for the plastic manufacturing process. They offer several benefits that contribute to the overall efficiency and effectiveness of the injection molding process. Here are some advantages of using a reciprocating cylinder in an injection molding machine:

1. Precise Control: Reciprocating cylinders provide precise control over the injection process, allowing for accurate and consistent plastic material delivery. The reciprocating motion of the cylinder ensures that the material is injected with a high level of repeatability, resulting in consistent part quality.

2. High Injection Speed: Injection molding machine reciprocating cylinders enable high injection speeds, which are crucial for achieving fast cycle times in injection molding. The rapid movement of the cylinder allows for quick filling of the mold cavity, reducing the overall production time.

3. Energy Efficiency: Reciprocating cylinders can be designed with energy-efficient features. By utilizing servo motors or hydraulic systems with variable displacement pumps, the energy consumption of the injection molding machine can be optimized. This results in lower operational costs and reduced environmental impact.

4. Versatility: Injection molding machine reciprocating cylinders can handle a wide range of plastic materials, including both thermoplastics and thermosetting plastics. The ability to process various materials makes them versatile for different applications and industries.

5. Ease of Maintenance: Reciprocating cylinders are relatively simple in design, making them easier to maintain compared to more complex systems. Routine maintenance tasks such as cleaning, lubrication, and inspections can be performed with relative ease, minimizing downtime and ensuring consistent machine performance.

6. Safety: Injection molding machine reciprocating cylinders can incorporate safety features such as pressure and temperature sensors, ensuring safe and controlled operation. These features help prevent accidents and protect both the operators and the machine.

Injection Molding Machine Reciprocating Cylinder Uses:

Reciprocating cylinders are a critical component of injection molding machines and serve several important purposes in the injection molding process. Here are some key uses of reciprocating cylinders in injection molding machines:

(1) Plastic Material Injection: The primary function of the reciprocating cylinder is to inject molten plastic material into the mold cavity. The reciprocating motion of the hydraulic cylinder enables precise control over the injection process, ensuring accurate and consistent delivery of the plastic material into the mold.

(2) Plasticizing and Melting: Reciprocating cylinders are responsible for plasticizing and melting the solid plastic material, transforming it into a molten state suitable for injection. The reciprocating motion of the cylinder, combined with heat and pressure, facilitates the melting process and ensures uniform plasticization of the material.

(3) Metering and Shot Size Control: Reciprocating cylinders play a crucial role in metering the precise amount of molten plastic material required for each shot. The cylinder's movement and design allow for accurate control over the volume of material injected, determining the size and weight of the final molded part.

(4) Injection Speed Control: Reciprocating cylinders enable control over the injection speed, which is essential for achieving optimal part quality. The speed at which the cylinder moves determines how quickly the molten plastic material fills the mold cavity. By adjusting the injection speed, operators can optimize the molding process to prevent defects like flow marks or air entrapment.

(5) Material Versatility: Reciprocating cylinders can handle a wide range of plastic materials, including various thermoplastics and thermosetting plastics. This versatility allows injection molding machines with reciprocating cylinders to accommodate different material properties, enabling the production of diverse plastic parts for various industries and applications.

China Injection Molding Machine Cylinder Manufacturers

In 30 years of focusing on innovation, HZPT has reached the forefront of the world’s hydraulic industry in terms of both production scale and technical level. Meanwhile, HZPT is now a widely recognized benchmarking enterprise in the domestic hydraulic industry. Headquartered in Hangzhou, HZPT has founded five hydraulic R&D centers in China, Germany, the United States, Japan, and Mexico, and ten manufacturing bases worldwide. HZPT the establishment of a high-precision foundry and a pump & valve factory, HZPT has mastered the key to developing and manufacturing more advanced hydraulic transmission and control components to supply high-pressure cylinders, hydraulic pump valves, motors, precision castings, and the complete hydraulic system. Well sold in over 20 countries and regions, the products are widely applied in various fields such as mobile machinery, agricultural machinery, industrial engineering, offshore, energy technology, and tunnel boring machines.

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders in China. In 2020, the domestic market share was around 29%. We produce industrial vehicle hydraulic cylinders, aerial work vehicle hydraulic cylinders, mobile machinery cylinders, industrial engineering hydraulic cylinders, construction machinery hydraulic cylinders, forklift hydraulic cylinders, crane luffing hydraulic cylinders, and sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

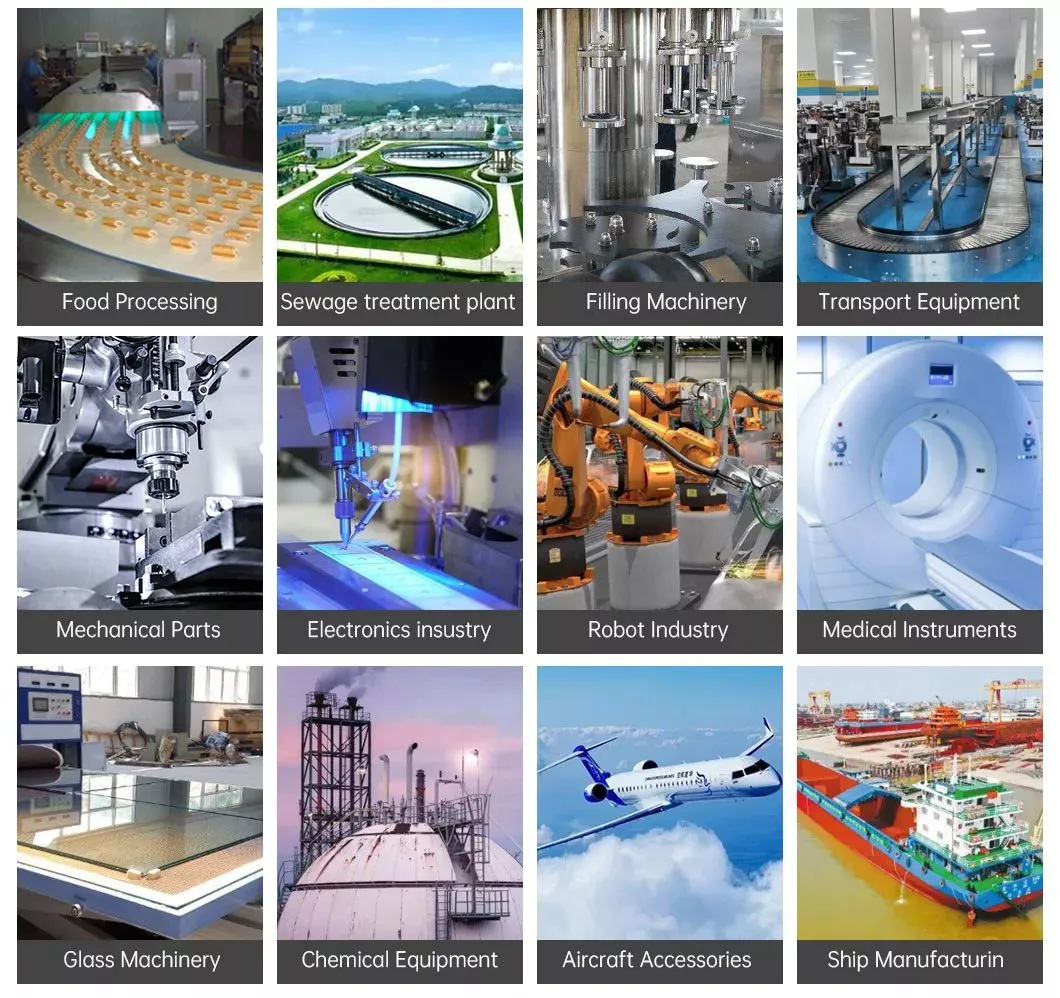

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder