Custom Made Hydraulic Cylinder for Industrial Vehicle/Forklift Tilt Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

A forklift hydraulic tilt cylinder is a double-acting hydraulic cylinder that is used to tilt the mast of a forklift. It is typically located at the rear of the forklift, and it is connected to the mast and the frame of the forklift. When hydraulic fluid is pumped into the cylinder, it extends the rod, which tilts the mast forward. When hydraulic fluid is pumped out of the cylinder, it retracts the rod, which tilts the mast backward.

The forklift hydraulic tilt cylinder is an important safety feature on a forklift. It allows the operator to tilt the mast forward to load or unload a pallet, and it also allows the operator to tilt the mast backward to dump a load. The tilt cylinder also helps to prevent the forklift from tipping over when the mast is tilted.

The forklift hydraulic tilt cylinder is typically made of steel and is coated with a protective finish. It is also equipped with seals to prevent leaks. The tilt cylinder is a critical component of a forklift, and it should be regularly inspected and maintained to ensure safe operation.

Here are some of the key features of a forklift hydraulic tilt cylinder:

- Double-acting: The hydraulic tilt cylinder can extend and retract, which allows the mast to be tilted in both directions.

- Heavy-duty construction: The hydraulic tilt cylinder is made of strong materials to withstand the weight of the load and the forces of operation.

- Durable seals: The seals prevent leaks and keep the hydraulic fluid contained.

- Regular inspection and maintenance: The hydraulic tilt cylinder should be inspected and maintained regularly to ensure safe operation.

Forklift Hydraulic Tilt Cylinder Key Attributes:

| Condition: | New | Product name: | Forklift Hydraulic Tilt Cylinder |

| Warranty: | 1 Year | Application: | Industrial vehicle/forklift tilt |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Retail, Construction works, Energy & Mining | Color: | Customer Requirement |

| Weight (KG): | 100 | Material: | 20#/45# Steel |

| Video outgoing inspection: | Provided | Acting type: | Double Acting, Single Acting |

| Machinery Test Report: | Provided | Seals: | Hallite,parker, NOK,Shamban |

| Marketing Type: | Ordinary Product | Certificate: | ISO9001:2015 |

| Warranty of core components: | 1 Year | MOQ: | 1Pcs |

| Core Components: | Piston rod, Piston | Brand: | EPT |

| Standard or Nonstandard: | Nonstandard | Quality: | 100% Tested |

| Structure: | Piston Cylinder | Packaging Details: | Crate, pallet, or based on customer's requirement |

| Power: | Hydraulic | Supply Ability | 100,000 Piece/Pieces per Month |

| Body Material: | Steel | Port: | Shanghai/Ningbo |

Forklift Hydraulic Tilt Cylinder Parameter:

| Item | Description |

| Product Name | Custom-made hydraulic Cylinder for industrial vehicles, forklift tilt |

| Certificate: | ISO9001, ISO4001, ISO 45003 |

| Production Capacity: | 1200,000 pcs per year |

| Sample Time | Based actual type |

| Brand | EPT or customer's logo |

| Service | OEM & ODM |

| Seal brand | Parker,NOK, BUSAK SHAMBAN |

| Delivery Time | Based on order quantity. |

| Business Type | Manufacturer & Exporter |

Forklift Hydraulic Tilt Cylinder Parts:

|

1

|

Cylinder Housing assy

|

10

|

Guide Bush

|

18

|

Circlips For Shaft

|

|

2

|

Piston Rod

|

11

|

Dust Wiper

|

19

|

Plug

|

|

3

|

Piston

|

12

|

U-Ring

|

20

|

Clevis

|

|

4

|

Hex Nut

|

13

|

Rod Seal

|

21

|

Grease Nipple

|

|

5

|

Cotter Pins

|

14

|

Du Bush

|

22

|

Bolt

|

|

6

|

O-Ring

|

15

|

O-Ring

|

23

|

Spring Washers

|

|

7

|

Back-Ring

|

16

|

Round Wire

|

24

|

Nut

|

|

8

|

Hole Seal

|

17

|

Key Ring

|

25

|

Spherical Bearing

|

|

9

|

Wear-Ring

|

Forklift Hydraulic Tilt Cylinder Features:

Forklift hydraulic tilt cylinders for all industries. We can build, supply new, and repair cylinders for earth moving, marine, press, crane, telescopic, shear, excavator, and chip dump applications. We also have the capabilities, experience, and technical knowledge to manufacture new cylinders and custom-build cylinders. We can handle any forklift hydraulic cylinder needs, from smaller application cylinders to very large cylinders (for example, cylinders on large mining equipment). Contact us for pricing and availability or if you need a custom hydraulic tilt cylinder.

--3000PSI Rated pressure, 6000PSI testing pressure.

---Imported world-famous brands and Chinese top brands are sealing systems.

---High-quality Cold Drawn steel tube, with good rigidity.

---CNC Rolled tube inner surface, with roughness of 0.2~0.4um.

---Superior strength chrome-plated rod, anticorrosion for a long life.

---High-grade Ductile Iron bar directly machined Gland and Piston, with high strength.

---Heavy-duty welded construction, automatic welding for good quality.

---Twin-lip piston seals for maximum efficiency.

---100% factory tested under at least 1.5 times of the rated pressure.

How Does a Forklift Hydraulic Tilt Cylinder Work?

A forklift hydraulic tilt cylinder is a vital component of a forklift's mechanism that enables the lifting and tilting of the load. It works based on the principles of fluid mechanics and hydraulic systems. Here's an outline of how it functions:

- Principle of Hydraulic Systems: The basic principle behind any hydraulic system, including a forklift's hydraulic tilt cylinder, is Pascal's law, which states that when a change in pressure is applied to an enclosed fluid, it is transmitted undiminished to all portions of the fluid and to the walls of its container. This means that if you exert pressure on one end of a hydraulic system, the same pressure is realized at the other end of the system.

- Parts of a Hydraulic Tilt Cylinder: The hydraulic tilt cylinder in a forklift typically consists of a cylinder barrel, a piston that can move back and forth within the barrel, and hydraulic fluid. The cylinder is often connected to the forklift's mast, which holds the forks.

- Operation: When the operator wishes to tilt the mast and, hence, the forks, they will activate the relevant controls in the forklift's cab. This sends a signal to a pump, which starts to force hydraulic fluid into the cylinders under high pressure.

- Tilt Backward: When the operator wants to tilt the load backward for stability during transport, the hydraulic fluid is pumped into the bottom of the cylinder. The increase in pressure pushes the piston upward, which in turn pulls the rod upward, causing the mast to tilt backward.

- Tilt Forward: To tilt the load forward (for instance, to unload), the process is reversed. The hydraulic fluid is pumped into the top part of the cylinder, forcing the piston and the rod to move downward, tilting the mast forward.

- Retraction: Once the tilting action is complete, the hydraulic fluid is allowed to flow back out of the cylinder, and the piston returns to its original position. This is often achieved by releasing the pressure in the system, allowing the weight of the mast and any load it's carrying to push the fluid back toward the hydraulic reservoir.

- Seals: Seals and wipers in the hydraulic tilt cylinder prevent the leakage of hydraulic fluid and keep contaminants from entering the system.

Remember, the efficiency of a hydraulic system depends on maintaining the right amount of pressure and ensuring the system is free from air bubbles. Regular maintenance is crucial to keep the hydraulic tilt cylinder and the overall hydraulic system of a forklift in good working order.

China Hydraulic Cylinder Manufacturers

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce Industrial vehicle hydraulic cylinders, Aerial work vehicle hydraulic cylinders, Agricultural Machinery hydraulic cylinders, Construction machinery hydraulic cylinders, and Sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

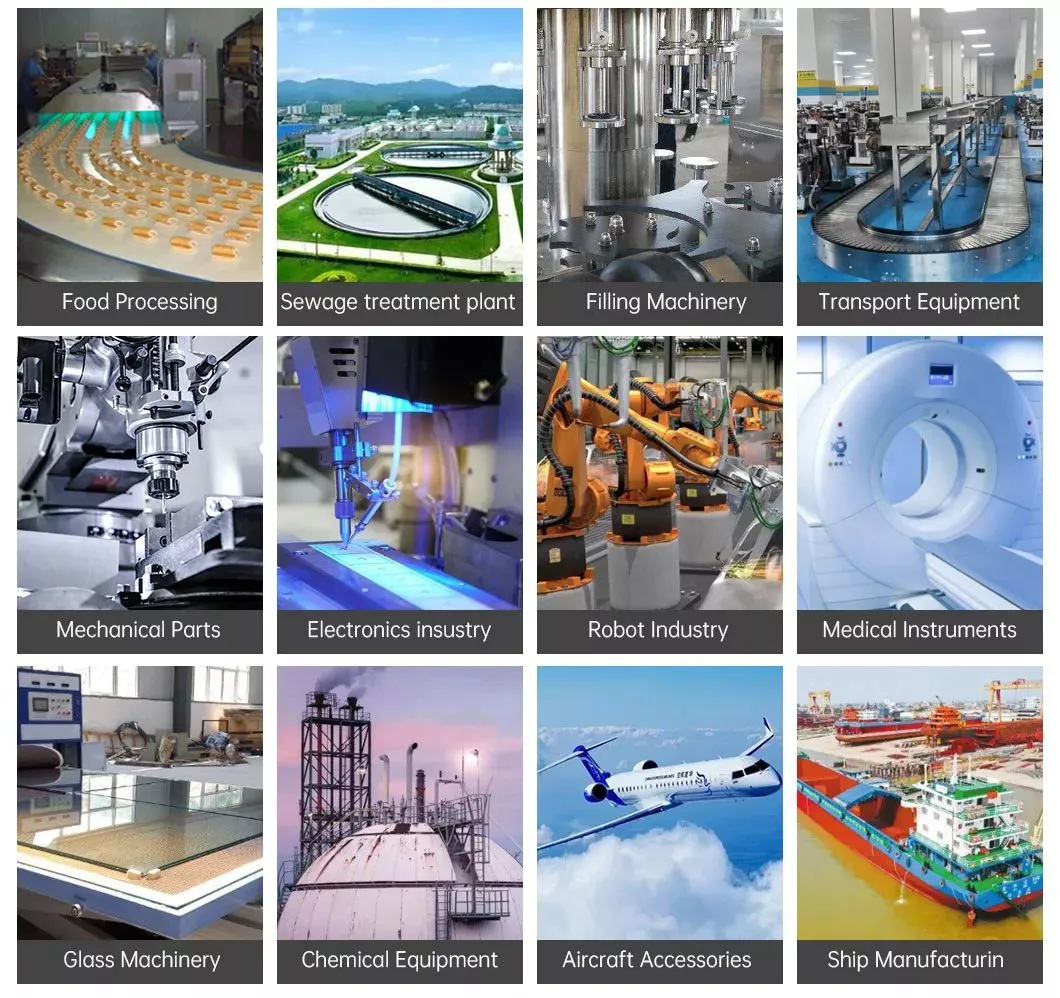

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder