Crane Counterweight Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

A crane counterweight hydraulic cylinder is a type of hydraulic cylinder that is used to raise and lower the counterweight on a crane. The counterweight is a heavy weight that is placed at the back of the crane to help balance the load that the crane is lifting. The hydraulic cylinder uses pressurized oil to extend and retract the piston, which raises and lowers the counterweight.

The crane counterweight hydraulic cylinder is an important safety feature that helps to prevent the crane from tipping over. When the crane is lifting a load, the weight of the load is balanced by the weight of the counterweight. If the counterweight is not properly balanced, the crane could tip over.

The crane counterweight hydraulic cylinder is also important for the efficiency of the crane. When the counterweight is raised, the crane can lift a heavier load. When the counterweight is lowered, the crane can lift a lighter load. This allows the crane to be used for a wider range of tasks.

The crane counterweight hydraulic cylinder is a complex and precision-engineered component. It must be able to withstand the weight of the counterweight and the forces generated by the hydraulic system. It must also be able to operate smoothly and reliably.

Here are some of the key features of a crane counterweight hydraulic cylinder:

- It is made of strong and durable materials, such as steel or aluminum.

- It has a thick piston rod that can withstand the weight of the counterweight.

- It has a high-pressure hydraulic system that provides the power to raise and lower the counterweight.

- It has a smooth and precise operating mechanism that minimizes wear and tear.

- It is designed to be safe and reliable, with features such as fail-safe valves and pressure relief valves.

The crane counterweight hydraulic cylinder is a vital component of the crane. It helps to keep the crane safe and efficient, and it allows the crane to be used for a wider range of tasks.

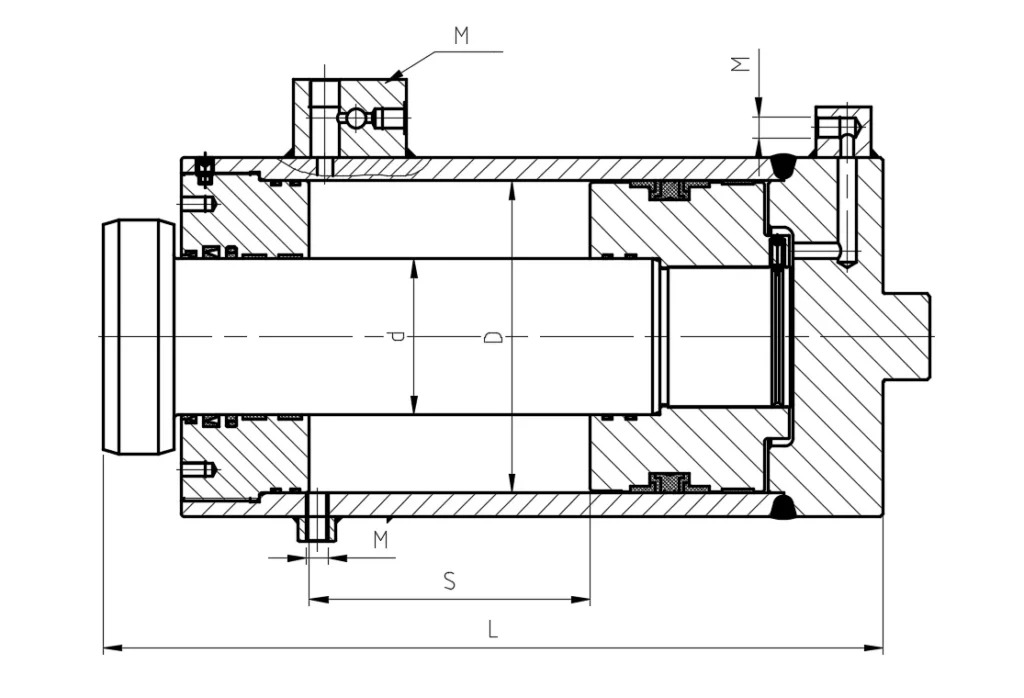

Crane Counterweight Hydraulic Cylinder Dimensions:

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Counterweight hydraulic cylinder | QAY220.12/13A-00 | Φ200 | Φ100 | 180 | 530 | 25MPa;40MPa | 3-G1/4;M20*1.5;2-M14*1.5 | 124kg |

Crane Counterweight Hydraulic Cylinder Parameter:

| Item | Description |

| Product Name | Custom-made hydraulic Cylinder |

| Certificate: | ISO9001, ISO4001, ISO 45003 |

| Production Capacity: | 1200,000 pcs per year |

| Sample Time | Based actual type |

| Brand | EPT or customer's logo |

| Service | OEM & ODM |

| Seal brand | Parker,NOK, BUSAK SHAMBAN |

| Delivery Time | Based on order quantity. |

| Business Type | Manufacturer & Exporter |

How Does the Crane Counterweight Hydraulic Cylinder Work?

The crane counterbalance hydraulic cylinder is a complex system that requires precise control to function properly. The amount of fluid that is pumped into the cylinder is carefully regulated by a counterbalance valve. This valve ensures that the counterweight moves up at a controlled rate and does not overshoot its target position.

The crane counterbalance hydraulic cylinder is made up of the following parts:

- Piston rod: The piston rod is a long, cylindrical rod that extends through the center of the cylinder. It is connected to the counterweight by a chain or cable.

- Piston: The piston is a disc-shaped object that is located inside the cylinder. It is attached to the piston rod and moves up and down as fluid is pumped into and out of the cylinder.

- Cylinder bore: The cylinder bore is the hollow space inside the cylinder that the piston moves through.

- Hydraulic hose: The hydraulic hose connects the cylinder to the hydraulic pump. It carries pressurized fluid to the cylinder.

- Counterbalance valve: The counterbalance valve is a device that regulates the flow of fluid into the cylinder. It prevents the piston from moving too quickly or too slowly.

When the crane operator lifts a load, the hydraulic pump sends pressurized fluid to the cylinder. The fluid enters the cylinder through the hydraulic hose and pushes on the piston. The piston moves up, which moves the counterweight up. This helps to balance the weight of the load and prevent the crane from tipping over.

The counterbalance valve ensures that the piston moves up at a controlled rate. The valve has a spring-loaded plunger that opens and closes to regulate the flow of fluid into the cylinder. When the plunger is fully open, the fluid flows freely into the cylinder, and the piston moves up quickly. When the plunger is partially closed, the fluid flows more slowly and the piston moves up more slowly.

The counterbalance hydraulic cylinder is a vital safety feature of a hydraulic crane. It helps to prevent accidents and injuries by keeping the crane stable during lifting operations.

China Hydraulic Cylinder Manufacturers

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce Industrial vehicle hydraulic cylinders, Aerial work vehicle hydraulic cylinders, Agricultural Machinery hydraulic cylinders, Construction machinery hydraulic cylinders, and Sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder