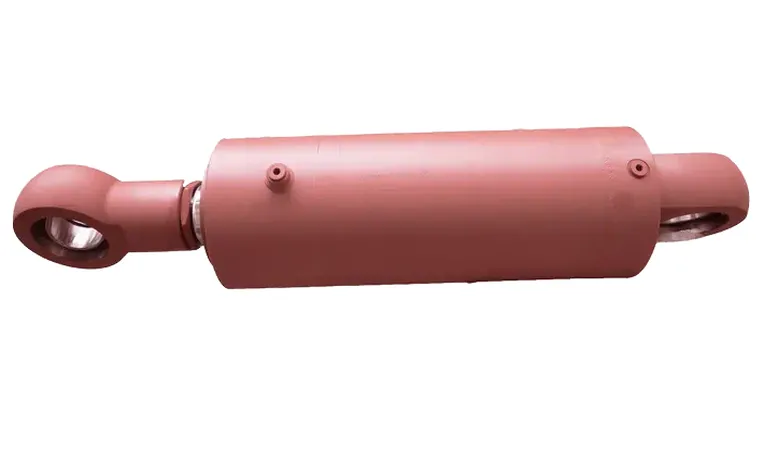

Sanitation Machinery Reverse Thrust Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

The sanitation machinery forward thrust hydraulic cylinder is a crucial component used in sanitation machinery and equipment specifically designed to provide powerful forward thrusting force. It plays a vital role in various applications such as street sweeping machines, garbage compactors, sewer cleaning vehicles, and other sanitation equipment that require efficient forward movement.

This sanitation machinery forward thrust hydraulic cylinder is specifically designed to convert hydraulic energy into linear motion, generating the necessary force for propulsion. It consists of a cylindrical barrel, a piston, a piston rod, and hydraulic ports. The cylinder barrel houses the piston, which divides the internal space into two chambers: the rod side and the cap side.

The hydraulic fluid, typically oil, is directed into one of the chambers through the hydraulic ports, creating pressure that pushes against the piston. As the pressure increases, it forces the piston and the connected piston rod to extend or retract, depending on the specific application. This linear motion translates into the forward thrust needed for the sanitation machinery to move efficiently.

The design and specifications of the sanitation machinery forward thrust hydraulic cylinder can vary depending on the application and specific requirements of the sanitation equipment. Factors such as maximum thrust force, stroke length, operating pressure, and environmental conditions are taken into account during the design process to ensure optimal performance and durability.

In summary, the sanitation machinery forward thrust hydraulic cylinder is a vital hydraulic component that provides the necessary forward thrusting force for various sanitation equipment. Its efficient and reliable operation contributes to the smooth and effective functioning of sanitation machinery, ultimately helping to maintain cleanliness in urban environments.

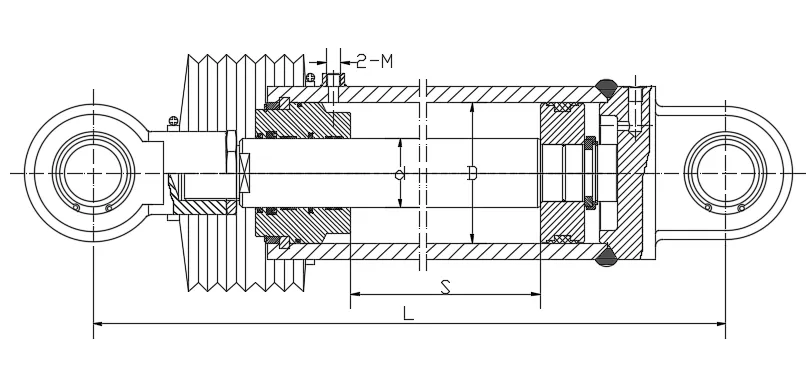

Sanitation Machinery Reverse Thrust Hydraulic Cylinder Dimensions:

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Reverse thrust cylinder | LPE222.2.2-5-00 | Φ220 | Φ110 | 420 | 1110 | 16MPa | 2-M22*1.5 | 323kg |

Sanitation Machinery Reverse Thrust Hydraulic Cylinder Parts:

The main parts of a sanitation machinery reverse thrust hydraulic cylinder are:

1. Cylinder Barrel: The cylinder barrel is the main body of the reverse thrust cylinder. It houses the piston and provides a sealed chamber for the hydraulic fluid.

2. Piston: The piston is a cylindrical component that moves back and forth inside the reverse thrust cylinder barrel. It divides the cylinder into two chambers and transmits the hydraulic force generated by the fluid.

3. Piston Rod: The piston rod is attached to the piston and extends through one end of the cylinder barrel. It provides a connection point for external components and transfers the force from the piston to the machinery.

4. Seals: Seals are crucial for maintaining the integrity of the hydraulic system. They prevent leakage of hydraulic fluid and help maintain pressure within the reverse thrust cylinder. Common seal types include rod seals, piston seals, and wiper seals.

5. Hydraulic Fluid: Hydraulic fluid, often oil, is used to transmit force within the reverse thrust cylinder. It is pressurized by a hydraulic pump and distributed throughout the reverse thrust cylinder to generate movement.

6. Cylinder Head and Cap: The reverse thrust cylinder head and cap enclose the ends of the cylinder barrel, providing a sealed structure. They typically have ports for hydraulic fluid inlet and outlet.

7. Mounting Brackets: Mounting brackets are used to attach the hydraulic cylinder to the sanitation machinery. They provide stability and ensure proper alignment for efficient operation.

8. Retainer Rings: Retainer rings or circlips are used to secure the piston and other components within the reverse thrust cylinder barrel. They prevent disassembly during operation and maintenance.

9. Hydraulic Connections: Various hydraulic connections, such as fittings, hoses, and valves, are used to facilitate the flow of hydraulic fluid into and out of the reverse thrust cylinder.

China Hydraulic Cylinder Manufacturers

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce Industrial vehicle hydraulic cylinders, Aerial work vehicle hydraulic cylinders, Agricultural Machinery hydraulic cylinders, and Sanitation machinery hydraulic cylinders.

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standar

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder