Hydraulic Cylinders for Desalination Equipment

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

Desalination equipment hydraulic cylinders are a type of hydraulic cylinder that is specifically designed for use in desalination plants. Desalination equipment hydraulic cylinders must be able to withstand the harsh operating conditions found in desalination plants. This includes exposure to salt water, high temperatures, and corrosive chemicals. Desalination equipment hydraulic cylinders are also required to be highly reliable and durable, as they must operate for many years without failure.

There are two main types of desalination equipment hydraulic cylinders: single-acting and double-acting cylinders. Single-acting cylinders are only powered in one direction while double-acting cylinders are powered in both directions. Desalination equipment hydraulic cylinders are typically double-acting cylinders, as this allows them to provide more power and control.

Desalination equipment hydraulic cylinders are made from a variety of materials, including steel, stainless steel, and aluminum. The choice of material depends on the specific application and the operating environment. For example, stainless steel hydraulic cylinders are often used in desalination plants that use seawater, as they are more resistant to corrosion.

Desalination equipment hydraulic cylinders are an essential part of many desalination plants. They provide the power and control needed to operate the various components of the plant and produce fresh water. They are used in a variety of applications, including:

- Moving valves: Hydraulic cylinders are used to move valves in desalination plants to control the flow of water and brine.

- Operating pumps: Hydraulic cylinders are used to operate pumps that circulate water and brine through the desalination plant.

- Operating filters: Hydraulic cylinders are used to operate filters that remove impurities from the water.

- Operating actuators: Hydraulic cylinders are used to operate actuators that control the movement of various components in the desalination plant.

Desalination Equipment Hydraulic Cylinder Specifications:

| Product Name | Hydraulic Cylinders for Desalination Equipment |

| Features: | Extract and compress the seawater and deliver it to the filtering device. |

| Bore diameter: | Up to 300mm |

| Rod diameter: | Up to 185mm Stroke up to 1000mm |

| Working temperature: | -20~30℃ |

| Working speed: | up to 110mm/s |

| Working frequency: | 24 hours |

| Internal and external leakage: | < 5ml/min |

| Pressure: | up to 11MPa starting pressure<0.1Mpa |

| Applications: | Desalination Equipment |

Desalination Equipment Hydraulic Cylinder Design Features:

• The duplex stainless steel, with no welds, effectively resists the corrosion of seawater.

• The hydraulic cylinder barrel and piston rod are painted with ceramics to increase surface wear resistance and durability.

• Special customized sealing forms and sealing materials are used to scrape microbes and fine sand in seawater to ensure the reliability and durability of the seal to the greatest extent.

• Special customized seawater inlet and outlet valve design to ensure the effective transportation of seawater.

• Special assembly and degreasing process; there can be no oil stains in the hydraulic cylinder.

Benefits of Hydraulic Cylinders in Desalination Equipment:

Hydraulic cylinders offer a number of benefits for desalination equipment, including:

1. High power-to-weight ratio: Hydraulic cylinders can provide a significant amount of force with a relatively small weight. This is important for desalination equipment, which often needs to move heavy components, such as RO membranes or brine collectors.

2. Variable speed control: Hydraulic cylinders can be controlled to move at a variety of speeds, depending on the application. This allows for precise control of desalination processes, such as the rate of brine rejection or the speed of membrane cleaning.

3. Positioning accuracy: Hydraulic cylinders can be used to position desalination equipment components with high accuracy. This is important for ensuring that the equipment operates properly and efficiently.

4. Efficient energy use: Hydraulic systems are relatively efficient in terms of energy use. This is important for desalination plants, which need to operate on a continuous basis.

5. Durability and reliability: Hydraulic cylinders are durable and reliable components. They can withstand the harsh conditions that often exist in desalination plants, such as high temperatures and corrosive chemicals.

Desalination Equipment Hydraulic Cylinder Applications:

Hydraulic cylinders are widely used in various applications across different industries. When it comes to desalination equipment, hydraulic cylinders can be used for several purposes. Here are some common applications of hydraulic cylinders in desalination equipment:

(1) Reverse Osmosis (RO) Systems: Reverse osmosis is a widely used method for desalination, and hydraulic cylinders play a crucial role in this process. They are used to control the pressure exerted on the RO membranes. Hydraulic cylinders help maintain the optimal pressure required for the desalination process by adjusting the position of the pressure vessels and regulating the flow of water through the membranes.

(2) Valves and Dampers: Desalination equipment often includes valves and dampers that control the flow of water, chemicals, and other fluids. Hydraulic cylinders are used to actuate these valves and dampers, allowing precise control over the flow rates and pressures within the system. They help in achieving accurate and efficient operation of the desalination equipment.

(3) Intake and Outfall Systems: Desalination plants typically require intake and outfall systems to draw seawater and discharge brine, respectively. Hydraulic cylinders can be employed in these systems to control the movement of intake screens, gates, and valves. They enable smooth and controlled operation for efficient water intake and brine disposal.

(4) Energy Recovery Systems: Energy recovery devices, such as pressure exchangers or turbines, are commonly used in desalination plants to optimize energy consumption. Hydraulic cylinders are utilized to control the position and movement of these devices, enabling efficient energy recovery from the high-pressure brine streams.

(5) Pre-Treatment Processes: Desalination equipment often involves pre-treatment processes to remove impurities from seawater before it undergoes the main desalination process. Hydraulic cylinders can be used to control various components in these pre-treatment systems, such as screens, filters, and backwash systems, ensuring proper operation and maintenance.

The Role of Hydraulic Cylinders for Desalination Equipment:

Desalination is a process that takes away mineral components from saline water. It is an open-source incremental technology to realize the utilization of water resources. The total amount of fresh water can be increased, and the stable supply of water for coastal residents and industrial water supply can be guaranteed. The composite seawater tank for desalination device jointly designed and developed by HZPT and its partner adopts an integrated parallel design. The head and bottom of the tank are integrated with two sets of specially designed inlet and drain valves to control seawater and freshwater, respectively. Orderly in and out. The hydraulic cylinder is simple and integrated in appearance and structure, which is conducive to the convenient installation of the equipment.

Unlike conventional hydraulic cylinders, the composite seawater tank requires a very high level of corrosion resistance. All parts and components are made of duplex stainless steel, and there is no welding structure. Both the surface of the piston rod and the inner hole of the cylinder barrel are made of APS (plasma spray) oxide ceramic coating, which greatly improves the wear and corrosion resistance of the hydraulic cylinder and fully meets the high frequency (24 hours) continuous operation of the hydraulic cylinder.

In addition, the hydraulic cylinder also adopts a special sealing structure and sealing material. Under the premise of ensuring the sealing performance, operating speed, and frequency, it can be effectively applied to seawater media and scrape the crystals and sediment on hardware. At the same time, the sealing material also needs to meet the requirements of FDA certification (food grade) to ensure that the water quality is pollution-free and meets the requirements of drinking grade. As a new technical product, the composite seawater tank will play a very important role in the use of seawater resources in human daily life.

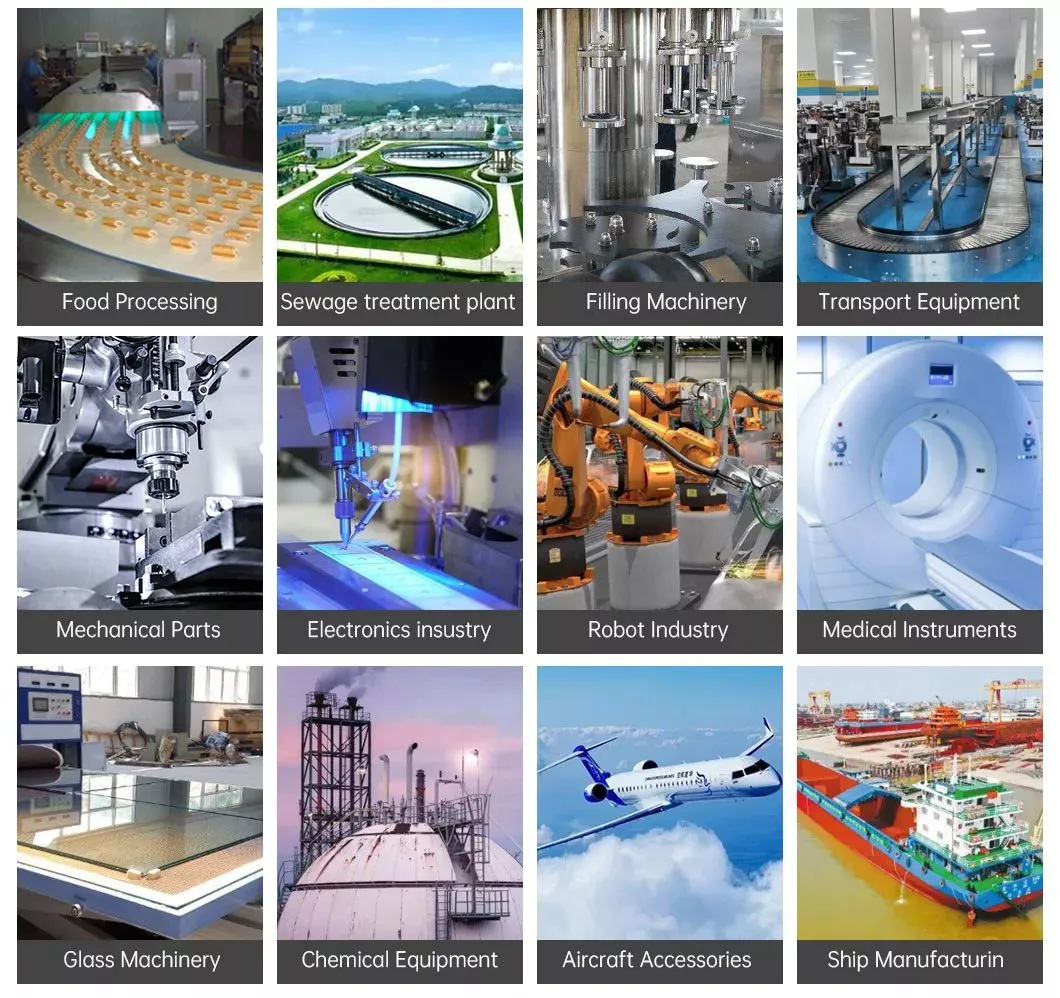

Moreover, we go beyond hydraulic cylinders for desalination equipment. We also supply a diverse range of hydraulic cylinders, including industrial vehicle hydraulic cylinders, aerial work vehicle cylinders, mobile machinery cylinders, industrial engineering cylinders, construction machinery cylinders, forklift hydraulic cylinders, agricultural machinery cylinders, crane hydraulic cylinders, sanitation machinery cylinders, excavator hydraulic cylinders, offshore hydraulic cylinders, energy technology cylinders, tunnel boring machine cylinders, and more. Our extensive product lineup caters to various industries and applications, providing solutions for your hydraulic needs.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder