Sanitation Machinery Locking Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

A sanitation machinery locking hydraulic cylinder is a type of hydraulic cylinder that is used to lock the position of a component in sanitation machinery. This type of cylinder typically has a spring-loaded or hydraulically-activated lock that prevents the rod from moving once it is in the desired position.

Sanitation machinery locking hydraulic cylinders is typically used in applications where there is a risk of the cylinder moving unexpectedly, such as in garbage trucks, sewage treatment plants, and other industrial settings. The locking mechanism can be either manual or automatic. Manual locking mechanisms require the operator to manually engage the lock, while automatic locking mechanisms engage the lock automatically when power is lost.

Sanitation machinery locking hydraulic cylinders is an important safety feature that helps to prevent accidents. They are used in a variety of applications where there is a risk of the cylinder moving unexpectedly.

Sanitation machinery locking hydraulic cylinders are used in a variety of applications, including:

- Sewage pumps: These cylinders are used to lock the position of the pump piston, preventing it from moving when the pump is not in use. This helps to prevent accidents and injuries.

- Waste compactors: These cylinders are used to lock the position of the compaction plate, preventing it from moving when the compactor is not in use. This helps to prevent injuries and damage to the compactor.

- Sludge shredders: These cylinders are used to lock the position of the shredding blades, preventing them from moving when the shredder is not in use. This helps to prevent injuries and damage to the shredder.

- Manhole covers: These cylinders are used to lock the position of manhole covers, preventing them from being opened by unauthorized personnel. This helps to prevent accidents and injuries.

Sanitation Machinery Locking Hydraulic Cylinder Dimensions:

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Locking cylinder | 107504-00 | Φ40 | Φ20 | 53 | 245 | 25MPa | 2-G3/8 | 2.6kg |

| Locking cylinder | 103631-00 | Φ63 | Φ40 | 160 | 385 | 30MPa | 2-G3/8 | 15kg |

Benefits of Sanitation Machinery Locking Hydraulic Cylinder:

Locking hydraulic cylinders are used in sanitation machinery to provide a secure and stable hold on objects. They have a number of benefits, including:

1. Precision control: Sanitation machinery locking hydraulic cylinders can be precisely controlled by adjusting the flow of hydraulic fluid. This allows for the precise positioning of objects, which is important in many sanitation applications. For example, in garbage trucks, the locking hydraulic cylinders must be able to precisely position the truck bed so that it is level when it is raised.

2. Safety: Sanitation machinery locking hydraulic cylinders help to prevent objects from moving unexpectedly. This is important in sanitation applications where there is a risk of objects falling or tipping over. For example, in sewer cleaning machines, the locking hydraulic cylinders prevent the boom from accidentally extending or retracting, which could injure the operator or damage the machine.

3. Durability: Sanitation machinery locking hydraulic cylinders are made from durable materials that can withstand the harsh conditions found in sanitation applications. For example, locking cylinders are often made from stainless steel or other corrosion-resistant materials.

4. Versatility: Sanitation machinery locking hydraulic cylinders can be used in a variety of sanitation applications. This makes them a versatile and cost-effective solution. For example, the cylinders can be used in garbage trucks, sewer cleaning machines, septic tank pumpers, and other equipment.

Sanitation Machinery Locking Hydraulic Cylinder Installation

Here are the steps on how to install a locking hydraulic cylinder on sanitation machinery:

(1) Disconnect the power to the machinery. This is a safety precaution to prevent accidental activation of the locking cylinder during installation.

(2) Remove the old cylinder. Use a wrench to loosen the bolts that secure the old cylinder in place. Once the bolts are loose, you can carefully remove the locking cylinder.

(3) Clean the mounting surface. Use a wire brush to remove any dirt, grease, or debris from the mounting surface. This will ensure a good seal between the locking cylinder and the mounting surface.

(4) Install the new cylinder. Align the new locking cylinder with the mounting holes and secure it in place with the bolts. Tighten the bolts to the specified torque.

(5) Connect the power to the machinery. Once the locking cylinder is installed, you can reconnect the power to the machinery.

(6) Test the cylinder. Activate the locking cylinder to make sure it is working properly.

China Hydraulic Cylinder Manufacturers

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce Industrial vehicle hydraulic cylinders, Aerial work vehicle hydraulic cylinders, Agricultural Machinery hydraulic cylinders, and Sanitation machinery hydraulic cylinders.

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

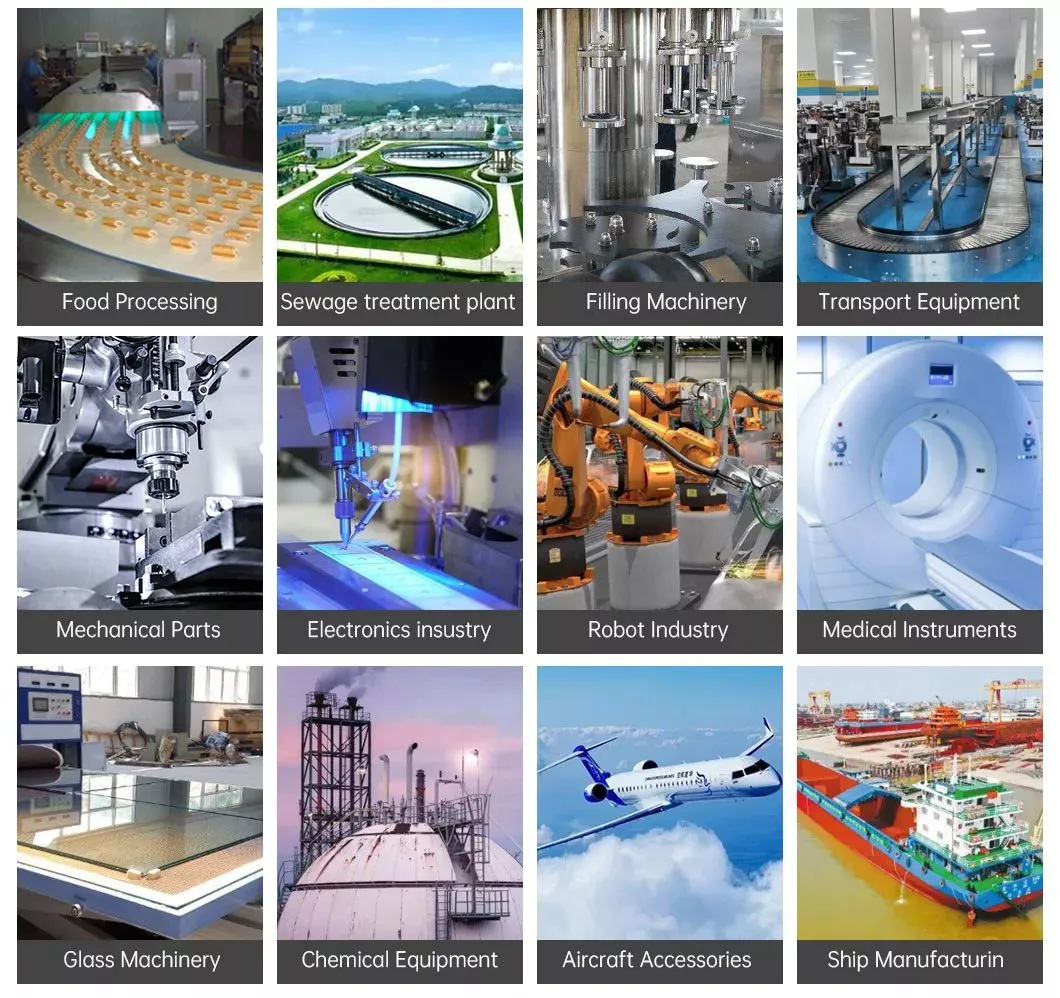

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder