Cement Equipment Feeding Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

A cement equipment feeding cylinder is a hydraulic cylinder that is used to promote the reciprocating movement of the grate bed of the grate cooler in a cement plant. It is a critical component of the cement production process, as it helps to ensure that the cement is evenly distributed and cooled.

The cement equipment feeding cylinder is typically made of high-strength steel and has a piston rod that is connected to the grate bed. The cylinder is operated by a hydraulic pump, which forces oil into the cylinder, causing the piston rod to extend. This movement of the piston rod moves the grate bed up and down, allowing the cement to be evenly distributed and cooled.

The cement equipment feeding cylinder is a high-pressure device, and it is important to use high-quality materials and components to ensure its safety and reliability. The cylinder should also be regularly inspected and maintained to ensure that it is in good working condition.

Here are some of the features and benefits of a cement equipment feeding cylinder:

- High strength and durability

- Long service life

- Ability to withstand high pressure

- Accurate and consistent movement

- Easy to operate and maintain

Cement equipment feeding cylinders are used in a variety of cement plants around the world. They are an essential part of the cement production process, and they help to ensure that the cement is evenly distributed and cooled.

Cement Equipment Feeding Cylinder Specifications:

| Product Name | Cement Equipment Feeding Cylinder |

| Features: | Promote the reciprocating movement of the grate bed of the grate cooler |

| Bore diameter: | 80mm~140mm |

| Rod diameter: | 45mm~80mm Stroke: ≤1200mm |

| Thrust force: | Max 385KN (Cylinder diameter 140mm/pressure 25MPa) |

| Cement Equipment Feeding Cylinder Applications: | Cement Equipment |

Cement Equipment Feeding Cylinder Advantages:

The cement equipment feeding cylinder offers several advantages in cement production plants. Some of the key advantages include:

1. Efficient Material Handling: The cement equipment feeding cylinder enables efficient storage and discharge of bulk materials. It ensures a controlled and regulated flow of raw materials, allowing for consistent and precise feeding to subsequent stages of the cement manufacturing process. This helps maintain optimal production rates and quality standards.

2. Improved Production Efficiency: By providing a continuous and automated material feed, the cement equipment feeding cylinder helps streamline the cement production process. It eliminates manual handling and reduces downtime associated with material replenishment, resulting in improved overall production efficiency and output.

3. Enhanced Material Protection: The cement equipment feeding cylinder is designed to withstand the abrasive nature of cement raw materials, protecting them from external elements and preventing contamination. It ensures that the materials remain intact and free from moisture or impurities during storage and discharge, thereby maintaining the quality of the final cement product.

4. Flexibility in Material Selection: The cement equipment feeding cylinder can handle a wide range of raw materials used in cement production, including limestone, clay, sand, and various additives. Its versatile design allows for easy adaptation to different material types and characteristics, accommodating variations in feedstock requirements.

5. Safety and Environmental Considerations: The cement equipment feeding cylinder can be equipped with safety features, such as level sensors and emergency shut-off mechanisms, to prevent potential accidents or material overflow. Additionally, it can integrate dust suppression systems to minimize dust emissions, promoting a safer working environment and reducing the impact on air quality.

6. Customization and Integration: The cement equipment feeding cylinder can be customized to meet specific plant requirements and seamlessly integrated into existing cement production systems. It can be designed to accommodate varying capacities, discharge rates, and material flow characteristics, ensuring compatibility with the overall plant layout and workflow.

How Does a Cement Equipment Feeding Cylinder Work?

A cement equipment feeding cylinder is a rotating cylinder that is used to feed cement into a grinding mill. The cylinder is typically made of steel and has a number of blades or paddles attached to its interior surface. As the cylinder rotates, the blades or paddles lift the cement and move it towards the discharge end of the cylinder. The cement is then discharged into the grinding mill, where it is ground into a fine powder.

The speed of rotation of the hydraulic cylinder is controlled by a variable frequency drive (VFD). The VFD allows the speed of rotation to be adjusted to match the flow rate of the cement. This ensures that the cement is fed into the grinding mill at a consistent rate.

The cement equipment feeding cylinder is a critical component of a cement plant. It ensures that the cement is fed into the grinding mill at a consistent rate, which is essential for producing high-quality cement.

Here are the steps on how a cement equipment feeding cylinder works:

- The cement is fed into the cylinder at the inlet end.

- The blades or paddles on the inside of the cylinder lift the cement and move it towards the discharge end.

- The cement is discharged into the grinding mill at the discharge end.

- The speed of rotation of the cylinder is controlled by a VFD to match the flow rate of the cement.

The cement equipment feeding cylinder is a relatively simple device, but it plays an important role in the production of cement. By ensuring that the cement is fed into the grinding mill at a consistent rate, the cylinder helps to produce high-quality cement.

Here are some of the factors that can affect the performance of a cement equipment feeding cylinder:

- The type of cement being fed into the cylinder.

- The moisture content of the cement.

- The flow rate of the cement.

- The speed of rotation of the cylinder.

- The condition of the blades or paddles on the inside of the cylinder.

If any of these factors are not ideal, it can affect the performance of the cylinder and lead to problems such as uneven feeding of the cement, clogging of the cylinder, or premature wear of the blades or paddles.

To ensure that the cement equipment feeding cylinder operates at its best, it is important to regularly inspect and maintain the cylinder. This includes checking the condition of the blades or paddles, cleaning the cylinder, and adjusting the speed of rotation of the cylinder as needed.

China Cement Equipment Cylinder Manufacturers

In 30 years of focusing on innovation, HZPT has reached the forefront of the world’s hydraulic industry in terms of both production scale and technical level. Meanwhile, HZPT is now a widely recognized benchmarking enterprise in the domestic hydraulic industry. Headquartered in Hangzhou, HZPT has founded five hydraulic R&D centers in China, Germany, the United States, Japan, and Mexico, and ten manufacturing bases worldwide. HZPT the establishment of a high-precision foundry and a pump & valve factory, HZPT has mastered the key to developing and manufacturing more advanced hydraulic transmission and control components to supply high-pressure cylinders, hydraulic pump valves, motors, precision castings, and the complete hydraulic system. Well sold in over 20 countries and regions, the products are widely applied in various fields such as mobile machinery, agricultural machinery, industrial engineering, offshore, energy technology, and tunnel boring machines.

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders in China. In 2020, the domestic market share was around 29%. We produce industrial vehicle hydraulic cylinders, aerial work vehicle hydraulic cylinders, mobile machinery cylinders, industrial engineering hydraulic cylinders, construction machinery hydraulic cylinders, forklift hydraulic cylinders, crane luffing hydraulic cylinders, and sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

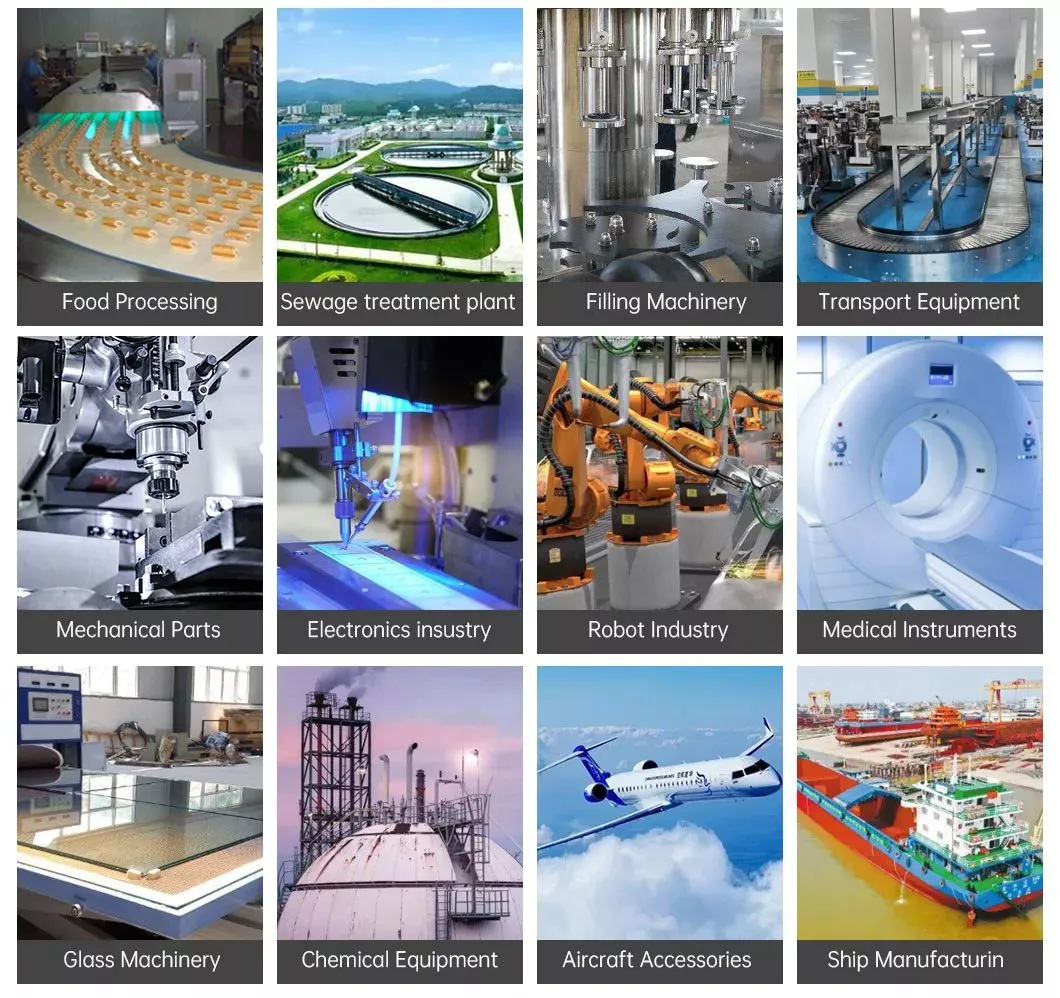

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder