Cement Equipment Roller Press Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

A cement equipment roller press cylinder is a hydraulic cylinder that is used to operate the roller press machine in a cement plant. The roller press is a type of grinding equipment that is used to reduce the size of raw materials and clinker in the cement manufacturing process.

The cement equipment roller press cylinder is typically a double-acting cylinder, meaning that it can apply force in both directions. This is necessary because the roller press has two rollers that rotate in opposite directions. The cylinder is used to move the movable roller towards and away from the fixed roller in order to adjust the gap between the rollers. This gap determines the size of the ground material that is produced by the roller press.

The cement equipment roller press cylinder is a critical component of the roller press machine. It must be able to withstand the high forces and harsh operating environment of the cement plant. Roller press cylinders are typically made of high-strength steel and are designed to have a long service life.

Here are some of the key features of a cement equipment roller press cylinder:

- Double-acting cylinder to apply force in both directions

- High-strength steel construction to withstand high forces and harsh operating environment

- Long service life

- Precision design to ensure accurate positioning of the movable roller

Cement Equipment Roller Press Cylinder Specifications:

| Product Name | Cement Equipment Roller Press Cylinder |

| Features: | Ensure the middle position of the clamp head |

| Bore diameter: | 200mm~700mm |

| Rod diameter: | 130mm~500mm Stroke: ≤500mm |

| Thrust force: | Max 5387KN (Cylinder diameter 700mm/pressure14MPa) |

| Cement Equipment Roller Press Cylinder Applications: | Cement Equipment |

Features of Cement Equipment Roller Press Cylinder:

Cement equipment roller press cylinders are the main working components of roller presses. They are responsible for applying the high pressure that crushes and grinds the material being processed.

Roller press cylinders are typically made of high-strength steel and are designed to withstand the extreme loads and pressures involved in the grinding process. They are also equipped with a variety of features to improve their performance and durability.

Some of the key features of cement equipment roller press cylinders include:

1. High-strength construction: Roller press cylinders are made of high-strength steel to withstand the extreme loads and pressures involved in the grinding process.

2. Precise machining: Roller press cylinders are precisely machined to ensure a smooth, frictionless surface and to maintain consistent pressure across the entire cylinder face.

3. Hardened surface: The surface of roller press cylinders is hardened to resist wear and abrasion.

4. Corrosion-resistant coating: Roller press cylinders are typically coated with a corrosion-resistant coating to protect them from the harsh environment in which they operate.

5. Heavy-duty seals: Roller press cylinders are equipped with heavy-duty seals to prevent leakage and contamination.

6. Easy maintenance: Roller press cylinders are designed to be easy to maintain and repair.

Cement Equipment Roller Press Cylinder Applications:

The cement equipment roller press cylinder finds its primary application in the cement industry, specifically in the grinding process of cement clinker. Here are some key applications of the roller press cylinder:

(1) Cement grinding: The roller press cylinder is a critical component of the roller press machine used for cement grinding. It applies high pressure to the grinding materials, such as clinker, slag, and raw coal, enabling efficient pulverization and fine grinding. This results in the production of finely ground cement, which is essential for high-quality cement products.

(2) Clinker grinding: Clinker, the main component of cement, is a hard, nodular material produced by heating limestone and other materials in a kiln. The roller press hydraulic cylinder is specifically designed to handle the grinding of clinker, ensuring its proper comminution and reducing it to fine particles. This process enhances the reactivity and consistency of clinker, leading to improved cement performance.

(3) Slag grinding: Slag, a by-product of the iron and steel industry, is often used as an additive in cement production. The roller press cylinder is capable of grinding slag materials, allowing for their effective utilization in cement blends. Grinding slag particles enhances their pozzolanic properties, contributing to the development of stronger and more durable cementitious materials.

(4) Raw coal grinding: In some cement manufacturing processes, raw coal is used as a fuel source. The roller press cylinder can handle the grinding of raw coal, ensuring its proper pulverization and reducing it to the desired particle size. This enables efficient combustion and energy generation within the cement production system.

(5) Energy-efficient grinding: The roller press cylinder is favored for its ability to achieve energy-efficient grinding. By exerting high pressure on the grinding materials, it reduces the energy required for comminution compared to traditional grinding methods. This contributes to lower energy consumption and reduced carbon emissions in cement manufacturing.

(6) Retrofitting and plant upgrades: The roller press cylinder can also be used in retrofitting existing cement grinding systems or as part of plant upgrades. By incorporating a roller press machine with the cylinder, cement plants can enhance their grinding capacity, improve product quality, and optimize energy efficiency without the need for extensive modifications to the existing infrastructure.

China Cement Equipment Cylinder Manufacturers

In 30 years of focusing on innovation, HZPT has reached the forefront of the world’s hydraulic industry in terms of both production scale and technical level. Meanwhile, HZPT is now a widely recognized benchmarking enterprise in the domestic hydraulic industry. Headquartered in Hangzhou, HZPT has founded five hydraulic R&D centers in China, Germany, the United States, Japan, and Mexico, and ten manufacturing bases worldwide. HZPT the establishment of a high-precision foundry and a pump & valve factory, HZPT has mastered the key to developing and manufacturing more advanced hydraulic transmission and control components to supply high-pressure cylinders, hydraulic pump valves, motors, precision castings, and the complete hydraulic system. Well sold in over 20 countries and regions, the products are widely applied in various fields such as mobile machinery, agricultural machinery, industrial engineering, offshore, energy technology, and tunnel boring machines.

HZPT is a company in the R&D and manufacture of hydraulic cylinders. It maintains a leading position in the market segment of hydraulic cylinders for forklifts in China. In 2020, the domestic market share was around 29%. We produce industrial vehicle hydraulic cylinders, aerial work vehicle hydraulic cylinders, mobile machinery cylinders, hydraulic press cushion cylinders, construction machinery hydraulic cylinders, forklift hydraulic cylinders, crane luffing hydraulic cylinders and sanitation machinery hydraulic cylinders. Hydraulic cylinder is a non-standard product and all products are independently developed by ourselves.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

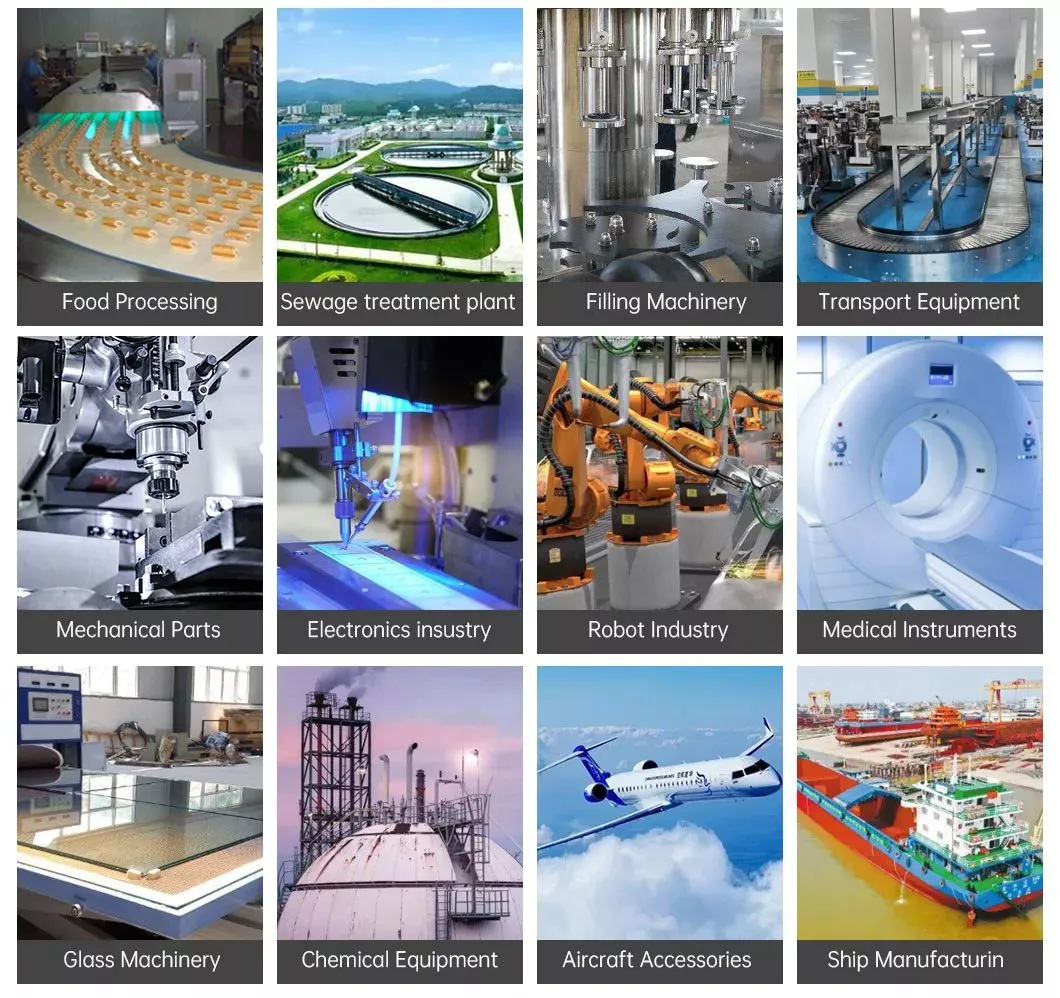

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder