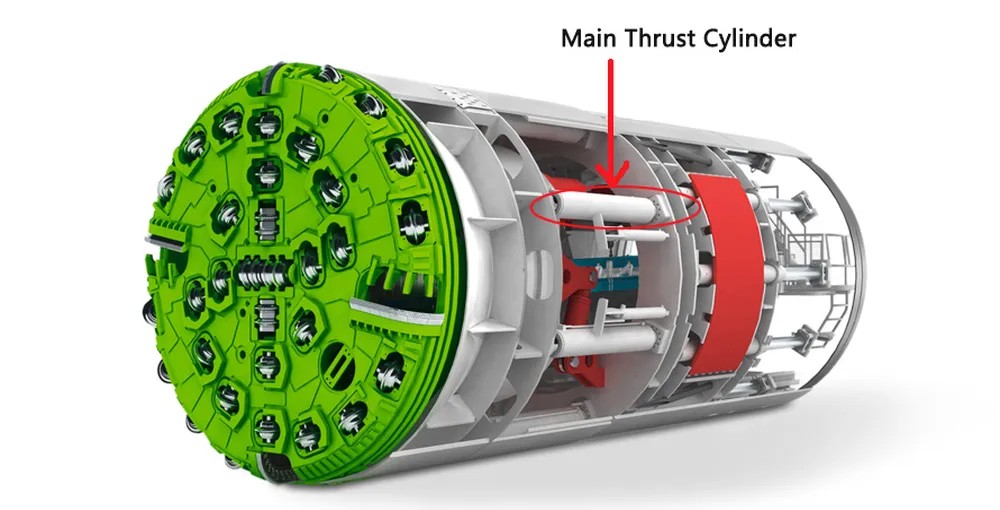

Double Shield Tunnel Boring Machine Main Thrust Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinders

The main thrust cylinder of a double shield tunnel boring machine (TBM) is the largest and most powerful cylinder on the machine. It is responsible for pushing the tunnel boring machine forward through the ground. The main thrust cylinder is typically located between the cutterhead and the gripper shield.

Double shield tunnel boring machines are used to bore tunnels in soft to medium-hard rock conditions. The main thrust cylinder is used to push the tunnel boring machine forward by reacting against the gripper shoes. The gripper shoes are extended into the tunnel walls to provide a reaction force. The main thrust cylinder then extends, pushing the tunnel boring machine forward.

The main thrust cylinder on a double shield tunnel boring machine is typically a single-acting cylinder. This means that it only extends in one direction. The cylinder is retracted using a hydraulic accumulator. The accumulator stores energy from the hydraulic system while the cylinder is extending. This energy is then used to retract the cylinder.

The main thrust cylinder on a double shield tunnel boring machine is a critical component of the machine. It must be designed to withstand the high forces and loads that are encountered during tunneling. The cylinder must also be reliable and durable, as it is in constant use.

Here are some of the key features of a double shield tunnel boring machine main thrust cylinder:

- Large diameter and stroke to provide the necessary force and displacement

- High-pressure rating to withstand the high loads encountered during tunneling

- Rugged construction to withstand the harsh operating environment

- Reliable and durable operation

Double shield tunnel boring machine main thrust cylinders are typically custom-designed and manufactured to meet the specific requirements of each project. The cylinder size, pressure rating, and other features are selected based on the tunnel diameter, rock conditions, and other factors.

Double Shield Tunnel Boring Machine Main Thrust Cylinder Specifications:

| Product Name | Double Shield Tunnel Boring Machine Main Thrust Cylinder |

| Features: | Provide the thrust of TBM forward tunneling |

| Bore diameter: | 220mm~380mm |

| Rod diameter: | 150mm~280mm Stroke: 1100mm~1700mm |

| Pressure: | up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield Tunnel Boring Machine Main Thrust Cylinder Benefits:

The main thrust cylinder of a double shield tunnel boring machine (TBM) is responsible for propelling the machine forward through the ground. It is one of the most important components of the tunnel boring machine, and its performance can have a significant impact on the overall progress of the tunneling project.

Here are some of the benefits of using a high-quality main thrust cylinder in a double shield tunnel boring machine:

1. Increased advance rates: A powerful main thrust cylinder can help the tunnel boring machine to advance through the ground more quickly, especially in hard rock conditions. This can lead to significant time savings and cost reductions for the tunneling project.

2. Reduced downtime: A well-designed and manufactured main thrust cylinder is less likely to fail, which can help to reduce downtime and keep the TBM on schedule.

3. Improved safety: A reliable main thrust cylinder is essential for the safety of the TBM operators and other personnel working on the tunneling project.

4. Longer service life: A high-quality main thrust cylinder can be expected to last for many years, even in demanding tunneling conditions. This can help to reduce the overall cost of ownership and maintenance of the tunnel boring machine.

In addition to these benefits, a good main thrust cylinder can also help to improve the accuracy and control of the tunneling process and reduce the environmental impact of the project.

Double Shield Tunnel Boring Machine Main Thrust Cylinder Uses:

The main thrust cylinder of a double shield tunnel boring machine (TBM) is used to push the machine forward as it excavates the tunnel. It is one of the most important components of the tunnel boring machine and is subjected to very high forces and loads.

The main thrust cylinder of a double shield tunnel boring machine is typically located at the rear of the machine and is connected to the grippers, which grip the tunnel walls and provide traction for the machine. The cylinder is powered by hydraulic fluid, which is pumped into the cylinder to create pressure. The pressure in the cylinder pushes the piston of the hydraulic cylinder forward, which in turn pushes the machine forward.

The main thrust cylinder of a double shield tunnel boring machine is used in a variety of applications, including:

- Tunneling through hard rock: Double shield tunnel boring machines are often used to tunnel through hard rock formations, such as granite and basalt. The main thrust cylinder provides the power needed to push the machine through this difficult terrain.

- Tunneling through mixed ground: Double shield tunnel boring machines can also be used to tunnel through mixed ground conditions, such as a combination of rock and soil. The main thrust cylinder provides the flexibility needed to adjust the thrust force to match the ground conditions.

- Tunneling in unstable ground: Double shield tunnel boring machines can also be used to tunnel in unstable ground conditions, such as clay and sand. The main thrust cylinder provides the controlled power needed to advance the machine without causing ground collapse.

In addition to these general applications, the main thrust cylinder of a double shield tunnel boring machine can also be used for specific tasks, such as:

- Steering the machine: The main thrust cylinder can be used to steer the machine by applying more thrust to one side of the machine than the other.

- Raising and lowering the machine: The main thrust cylinder can be used to raise and lower the machine to adjust its position in the tunnel.

- Installing tunnel segments: The main thrust cylinder can be used to install prefabricated concrete tunnel segments.

The main thrust cylinder of a double shield tunnel boring machine is a critical component of the machine and is essential for its successful operation. It is a powerful and versatile tool that can be used in a variety of tunneling applications.

Tunnel Boring Machine Hydraulic Cylinder Manufacturers

HZPT has been developing and producing tunnel boring machine cylinders since 2005, has successfully exported them all over the world, and has a leading global market share. For example, in the Bertha tunnel boring machine in Seattle, the entire set of high-pressure hydraulic cylinders is from HZPT. Even though the equipment was constructed underground for two years, HZPT's hydraulic cylinders did not suffer from corrosion and seal aging. We customized solutions for customers to fully meet the needs of complex working conditions such as high frequency, high load, vibration, and pollution during underground construction. HZPT uses its strength to build a comprehensive service brand for hydraulic transmission and control systems in the field of tunnel boring equipment.

In addition, we not only provide shield machine cylinders. We also supply a diverse range of hydraulic cylinders, including industrial vehicle hydraulic cylinders, aerial work vehicle cylinders, mobile machinery cylinders, industrial engineering cylinders, construction machinery cylinders, forklift hydraulic cylinders, agricultural machinery cylinders, crane hydraulic cylinders, sanitation machinery cylinders, excavator hydraulic cylinders, offshore hydraulic cylinders, energy technology cylinders, tunnel boring machine cylinders, and more. Our extensive product lineup caters to various industries and applications, providing solutions for your hydraulic needs.

We are one of the best hydraulic cylinders manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Application

Factory tour

Related products

-

Boom Aerial Work Vehicle Floating Hydraulic Cylinder

-

Boom Aerial Work Vehicle Lower Arm Hydraulic Cylinder

-

Boom Aerial Work Vehicle Steering Hydraulic Cylinder

-

Boom Aerial Work Vehicle Upper Arm Hydraulic Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Feeding Cylinder

-

Cement Equipment Roll over Cylinder

-

Cement Equipment Roll over Cylinder